VALVE REPLACEMENT

CB5A-021 page 17/24

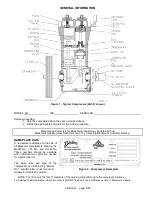

Figure 9 - Valve Location

Suction and discharge valves MUST be installed in the

correct cylinder head locations. See Figure 9.

The valves may be removed without removing the

cylinder head from the cylinder. Be sure to remove and

replace the valve gaskets.

Failure to install compressor valves

properly can lead to component failure,

personal injury or property damage.

Hazardous pressure

can cause serious

personal injury or

property damage

Failure to install compressor valves

properly can result in leakage of

explosive gas creating an explosion

hazard, possibly causing severe

personal injury or death.

Hazardous gases

can cause property

damage, personal

injury or death

Failure to install compressor valves

properly can result in extreme

discharge temperatures. This could be

an ignition source in the presence of

explosive gas possibly causing severe

personal injury or death.

Hazardous gases

can cause property

damage, personal

injury or death

MODELS LB161B or LB162B

- see Figure 10.

1. Remove the valve cap and O-ring from the valve

being serviced.

2. Remove the valve hold down screw with a spanner

wrench, such as Blackmer PN 790535.

3. Suction valve - Remove the liquid relief valve body,

valve assembly and gasket. DO NOT drop the liquid

relief ball and spring into the head interior.

4. Discharge valve - Remove the discharge valve cage,

valve assembly and gasket.

5. Inspect the valve for wear or breakage.

6. Ensure that the old gasket is removed, then install a

new valve gasket.

7. To reinstall the suction valves:

a. Install the valve assembly in the cylinder head.

Ensure the correct orientation and location of the

valve.

b. Center the liquid relief body on the valve

assembly.

c. Install the hold down screw and tighten per

Table 7 - "Bolt Torque."

d. Drop the liquid relief ball and the liquid relief

spring into the opening of the liquid relief body.

e. Insert the liquid relief adjusting screw and adjust

clockwise until the top of the screw is

approximately 3/8" (9.5 mm) above the top of the

liquid relief body. Add the locknut and tighten

securely.

8. To reinstall the discharge valves:

a. Install the valve assembly in the cylinder head.

Verify the correct valve orientation and location.

b. Center the valve cage on the valve assembly.

c. Install the hold down screw and tighten per

Table 7 - "Bolt Torque."

9. Install the valve cap and O-ring. A little oil or grease

on the O-ring will help hold it in place during

installation.

10. After replacing the valves, rotate the flywheel by

hand to check for interference between the pistons

and the valves.

11. After 60 minutes running time, remove the valve cap

and retorque the hold down screw. Replace the

valve cap and O-ring.

Figure 10 - LB161 or LB162 Valves