MAINTENANCE

CB5A-021 page 13/24

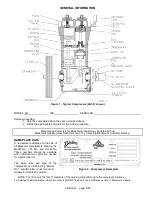

Figure 8 - Compressor Lubrication System

CRANKCASE LUBRICATION

Change the crankcase oil every 1,000 hours or 180 days,

whichever is shorter. Under severe dusty, sandy or wet

operating conditions, the oil should be changed every

500 hours or every 90 days.

If the crankcase oil becomes contaminated or diluted

due to gas leakage past the packing seals, the oil must

be changed more frequently. In such cases, change

the packing seals as soon as possible.

Non-detergent oils are recommended. Detergent oils

can be used providing the gas being handled does not

react with the detergent in the oil. If using a detergent

oil, be sure there is not a compatibility problem.

Ammonia, amine and imine gases are known to react

with many of the detergents in oil.

The oil used, detergent or non-detergent, should be

of high quality such as API grade SJ, SL, SM, SN or

similar.

API grade SA, SB, SC or similar oils should never

be used. Recycled oils should never be used.

Synthetic oils are acceptable; use the same guidelines

as mineral based lubricants. Consult factory for special

lubricating requirements.

Before changing the oil, bring the compressor up to

normal operating temperature. Remove the crankcase

drain plug and drain the oil into an adequately sized

container. Remove the oil pickup screen and clean in a

suitable solvent. When reinstalling the pickup screen,

inspect the metal gasket and the O-ring for damage,

replacing as necessary. If equipped, replace the external

oil filter. See Figure 8.

Refill the crankcase via the dipstick or nameplate

opening.

DO NOT OVERFILL THE CRANKCASE!

The oil pump on these models will operate in either

direction of crankshaft rotation.

Models

Quarts

Liters

LB161B, LB162B

LB361B, LB362C

LB601B, LB602B, LB602C

2

3

7

1.89

2.84

6.62

Table 8 - Oil Capacity

Mineral Based Oil - API Grade SN, SM, SL, SJ

ISO

Grade

SAE

Ambient

Temperature

Product

100

30

80°F (27°C)

and above

Mobil®

Rarus 427

or

equivalent

46

20

32 to 80°F

(0 to 27°C)

32

10

0 to 32°F

(-18 to 0°C)

22 - 15

5 - 0

Below 0°F

(-18°C)

Synthetic Oil

ISO

Grade

SAE

Ambient

Temperature

Product

68

20+

Full Range

Mobil®

SHC Rarus

68

or

equivalent

Table 10 - Oil Viscosity

SETTING THE OIL PRESSURE

(see Figure 8)

1. The oil pressure should be about 25 psig

(1.73 Barg).

2. Loosen the locknut.

3. Increase the pressure setting by turning the

adjusting screw inward, CLOCKWISE.

Decrease the pressure setting by turning the

adjusting screw outward, COUNTER-CLOCKWISE.

4. Retighten the locknut.