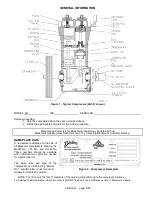

COMPRESSOR DISASSEMBLY

CB5A-021 page 15/24

Compressor

Model

Bushing I.D.

Inches (mm)

LB161B, LB162B

LB361B, LB362C

0.8753 to 0.8756

(22.233 to 22.240)

LB601B, LB602C,

LB602B

1.2511 to 1.2514

(31.778 to 31.786)

Table 10 - Wrist Pin Bushing Dimensions

12. To replace the crankshaft bearings, the crankcase

must be disassembled, and the crankshaft removed.

Refer to the "Bearing Replacement" section of this

manual.

COMPRESSOR ASSEMBLY

Compressor assembly is generally the opposite of

compressor disassembly. Before reassembling, clean

each part thoroughly. Check all machined surfaces for

burrs or roughness, and file lightly if necessary.

Replace

any O-rings or gaskets that are removed or disturbed

during service.

1.

CRANKCASE ASSEMBLY

After replacing the crankshaft, bearing carrier, and

bearing cover plate, the connecting rod and

crosshead can be assembled in the crankcase. See

the "Bearing Replacement" section.

a. To attach the connecting rod to the crosshead

assembly, first coat the wrist pin, the wrist pin

bore in the crosshead assembly, and the wrist

pin bushing in the connecting rod with grease.

b. Start the wrist pin in the bore of the crosshead

assembly until the pin begins to project through

to the inside of the crosshead assembly. (Use

an arbor press if available.)

c. Slide the connecting rod up inside of the

crosshead assembly and align the bushing with

the wrist pin.

d. Install the wrist pin through the connecting rod

until it is centered in the crosshead assembly.

The wrist pin should be snug in the crosshead

assembly. The connecting rod should rotate

freely on the wrist pin, but should not be loose.

e. Dip the wrist pin plugs in grease and press them

against the ends of the wrist pin.

f. Place the bearing halves into each half of the

connecting rod, aligning the bearing tangs with

the slots in the connecting rod. Coat the bearing

with grease.

g. Set the top of the connecting rod over the

crankshaft journal. Replace the connecting rod

cap with the dots on the connecting rod and cap

on the same side.

h. Start the nuts on the connecting rod bolts and

torque per Table 7 - "Bolt Torque."

i. Follow this same procedure for the opposite

connecting rod.

2.

CROSSHEAD GUIDE

a. Place the crosshead guide gasket on top of the

crankcase.

b. Lubricate the inside bore of the crosshead guide

with light oil.

c. Set the crosshead guide over the piston rods

and crossheads, and slowly lower it against the

crankcase. Make certain that the crosshead

assemblies are started straight in the bores of

the crosshead guide to prevent binding when

lowering the crosshead guide into position.

d. Install the crosshead guide capscrews. DO NOT

tighten.

3. Fill the crankcase with oil. Refer to the "Crankcase

Lubrication" section. Squirt oil into the crankshaft,

roller bearings, crankshaft journals, and crosshead

assemblies to ensure proper lubrication at start up.

4. Attach the inspection plate and the inspection plate

gasket to the crankcase.

5.

PACKING BOX ASSEMBLIES

Before installing the packing boxes into the

crosshead guide, inspect the piston rods for scoring

or roughness. Remove any burrs or sharp edges.

Lubricate the piston rods and packing box O-rings

with light oil.

Do not damage the packing when

starting it over the rod. Use of a Blackmer

packing installation tool is recommended, and

MUST be used on the LB602C.

(see ‘Tool List’

table).

Single-Seal Models

a. Insert the packing box O-ring into the crosshead

guide.

b. Start the packing box assembly, short end down,

over the piston rod and into the counter-bored

hole of the crosshead guide.

c. Install the packing box retainer ring, with new

nylon locking inserts, and tighten securely.

d. Repeat the above steps for the remaining

packing box.

Double-Seal Models

a. Insert the lower packing box O-ring into the

crosshead guide.

b. Start the packing box assembly, short end down,

over the piston rod and into the crosshead guide.