RCM

EDITION 09 / 2002

-

6

-

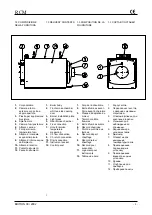

1.2 CARATTERISTICHE

TECNICHE GENERALI

I generatori di calore

BIASI

serie RCM sono generatori

in acciaio a combustione

pressurizzata che può

essere ottenuta sia con

combustibili liquidi che

gassosi.

Sono progettati per la

pressione massima di 4 bar

e sono del tipo a focolare

cieco cilindrico orizzontale

dimensionato per 2 giri di

fumo ad inversione di

fiamma; il terzo giro avviene

nel fascio tubiero.

All'interno del fascio tubiero

sono installati turbolatori,

costituiti da lame ondulate in

acciaio inossidabile che

aumentando la turbolenza

nel flusso di fumo,

migliorando lo scambio

termico e il rendimento del

generatore (superiore al

90%).

La porta anteriore è

normalmente predisposta

per il montaggio del

bruciatore previsto dal

cliente; al suo interno è

isolata con preformato

isolante/refrattario resistente

alle alte temperature

opportunamente sagomato

per convogliare verso il

fascio tubiero i fumi

provenienti dal focolare.

Le cerniere sono state

studiate per permettere

l’apertura della porta

anteriore indifferentemente

da destra o da sinistra.

Al di sopra della piastra di

fissaggio del bruciatore è

installato un manicotto con

spia in vetro pirex per

l'osservazione della fiamma

in camera di combustione.

Per raffreddare e mantenere

pulita la spia, essa è dotata

di attacco portagomma per il

collegamento alla presa

d'aria del bruciatore; lo

smontaggio temporaneo di

questo collegamento

permette la misura della

pressione in camera.

La camera a fumo posteriore

è imbullonata per consentire

la sua rimozione in

occasione di manutenzioni

straordinarie ed è dotata,

oltre che del raccordo fumi

1.2 GENERAL TECHNICAL

CHARACTERISTICS

BIASI

RCM steel boilers can

burn both liquid and gas

fuels. They are designed for

maximum 4 bar, and have

horizontal cylindrical

blank-back furnace with 2

smoke revolutions with

reverse flame and a third

revolution in the nest of

tubes.

Turbulators are installed in

the nest of tubes. These

consist of corrugated

stainless steel blades that

increase the turbulence of

the flow of smoke and

improve heat exchange and

boiler efficiency.

The front door is normally

designed to carry a burner

provided by the customer. It

is internally insulated with a

refractory/insulating casting

that resists high

temperatures and is

designed to convey smoke

coming from the furnace

towards the nest of tubes.

Hinges are designed to

permit the front door to open

either to the right or to the

left.

A sleeve is installed over the

burner fastening plate with a

Pyrex glass window to

observe the flame in the

combustion chamber.

The window has a hose

nipple connection that

connects to the burner's air

intake and functions to keep

the window clean and cool.

Temporary disconnection of

this connection permits the

pressure in the chamber to

be measured.

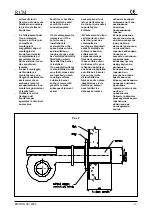

The rear smoke chamber is

bolted to permit removal

during extraordinary

maintenance. It also has, in

addition to the smoke fitting

for connection to the flue, a

removable inspection and

cleaning door and a

connection for draining off

any condensate.

The shell is insulated with

mineral wool mattresses.

External cladding is made of

internally insulated painted

steel sheet panels.

The support structure

consists of a sturdy

1.2 DESCRIPTION

La chambre de combustion

des chaudières

BIASI

RCM

est cylindrique, totalement

baignée et largement

dimensionnée pour

supprimer les contraintes

thermiques et de favoriser le

parcours de la flamme dans

le foyer borgne. Les

soudures sont toutes

exécutées en automatique

avec profils et bords

préalablement préparés.

La porte de la chaudière est

montée sur charnières.

L'ouverture est réglable à

droite ou à gauche pour les

modèles de 105 à 300 kW.

L'isolation haute

température de la porte est

conçue pour favoriser le

changement de direction

des produits de combustions

vers le faisceau tubulaire. La

chambre de combustion et

le faisceau tubulaire

présentent une grande

surface pour garantir un

excellant rendement.

Les tubes du faisceau sont

soudés aux plaques avant et

arrières sous "atmosphère

protégée".

Des chicanes en acier

inoxydable, insérées dans

les tubes ont pour rôle

d'augmenter la turbulence

des gaz de combustion et

d'accroître le coefficient de

transmission.

L'arrière du foyer de la

chaudière est équipé d'une

trappe de visite pour faciliter

l'entretien de la chaudière.

Les raccords de départ et de

retour chauffage sont placés

au-dessus de la chaudière

et sont équipés de brides et

de contre brides aux

dimensions normalisées.

Côté eau, des turbulateurs

favorisent l'échange

thermique évitant ainsi les

zones de surchauffe et de

stratification.

Les jaquettes des

chaudières sont en tôle

d'acier peinte, isolée à

l'intérieur (laine de verres en

couche comprimée).

Toutes les chaudières sont

essayées à la pression de

6,0 bars, pour une pression

1.2

ОБЩИЕ

ТЕХНИЧЕСКИЕ

ХАРАКТЕРИСТИКИ

Водогрейные

котлы

BIASI

серии

RCM

представляют

собой

стальные

котлы

с

герметичной

топкой

,

работающие

как

на

жидком

,

так

и

газообразном

топливе

.

Макс

.

рабочее

давление

4

бар

,

котлы

имеют

слепую

цилиндрическую

горизонтальную

топку

с

инверсией

пламени

,

размеры

которой

позволяют

уходящим

газам

совершать

два

оборота

,

третий

оборот

осуществляется

в

трубном

пучке

.

Внутри

трубного

пучка

установлены

спиральные

турбулизаторы

из

нержавеющей

стали

,

которые

,

увеличивая

турбулентность

в

потоке

дыма

,

улучшают

теплообмен

и

КПД

генератора

(

выше

90 %).

На

передней

дверце

устанавливается

горелка

,

выбранная

клиентом

;

внутри

она

покрыта

предварительно

отформованной

изоляцией

/

огнеупором

,

которая

особым

образом

профилирована

и

защищает

от

высоких

температур

;

она

направляет

в

трубный

пучок

уходящие

газы

из

топки

.

Шарниры

позволяют

открывать

переднюю

дверцу

как

налево

,

так

и

направо

.

Над

пластиной

для

закрепления

горелки

установлена

муфта

с

окошечком

из

стекла

пирекс

для

наблюдения

за

пламенем

в

камере

сгорания

.

Для

охлаждения

и

очистки

окошечко

оснащено

соединением

с

прокладкой

для

подключения

к

забору

воздуха

горелки

;

временный

демонтаж

этого

соединения

позволяет

измерить

давление

в

камере

.

Задняя

камера

дыма

привинчена

так

,

чтобы

обеспечить

ее

Summary of Contents for RCM 105

Page 2: ......