RCM

EDITION 09 / 2002

-

9

-

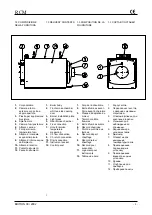

STRUMENTAZIONE ED

ACCESSORI

Le caldaie serie RCM sono

fornite complete dei seguenti

componenti:

-

pannello di comando e

controllo precablato

contenente:

termostati di regolazione

(pompa e bruciatore)

termostato di sicurezza a

riarmo manuale

termometro

interruttore di accensione

- pozzetto

per

termometro di prova

- piastra

forata

predisposta per

montaggio bruciatore

- materassino

in

fibra

ceramica per

tamponamento

boccaglio bruciatore

- serie

completa

di

turbolatori

- controflange

con

guarnizione e bulloni

(per gli attacchi flangiati)

scatola di cartone

contenente: materassino di

lana di vetro per isolamento

termico fasciame

pannellatura esterna

2. MONTAGGIO

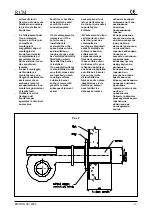

2.1 MONTAGGIO CALDAIA

- Posizionare

la

caldaia

sul piano previsto per la

sua installazione che

deve essere piano,

consentire un appoggio

continuo della struttura

di sostegno e

dimensionato per il peso

della caldaia stessa

piena d’acqua

- effettuare

un’ispezione

generale (compreso il

getto refrattario della

porta) per controllare

che la caldaia non abbia

subito danni durante il

trasporto

-

La caldaia dev’essere

posta in modo che,

rispetto alle pareti del

locale caldaia siano

rispettate le distanze

minime previste dai

regolamenti vigenti e sia

in ogni caso assicurato

un agevole accesso per

NSTRUMENTS AND

ACCESSORIES

RCM boilers are supplied

with the following

components:

-

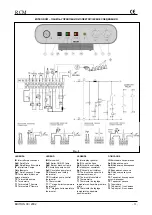

Prewired control panel

containing:

control thermostats

(pump and burner)

manually reset safety

thermostat

thermometer

main switch

-

test thermometer pocket

-

burner installation plate

-

ceramic fiber for

cladding the burner

nozzle

-

complete set of

turbulators

- counterflanges

with

gasket and bolts (for

flanged connections)

- cardboard

box

containing:

mineral wool for thermal

insulation

external casing

2. ASSEMBLY

2.1 BOILER ASSEMBLY

-

Position the boiler at its

installation site. This site

must be horizontal, give

uninterrupted support to

the boiler structure and

must be able to support

the weight of the boiler

when it is filled with

water.

- Perform

overall

inspection of the boiler

(including the door's

refractory casting) to

check that it has not

been damaged during

shipment.

-

The boiler must be

installed so that

distances from boiler

room walls comply with

the minimum distances

required by building

codes. Distances, in

any case, must

guarantee easy access

to the boiler for

APPAREILS DE

CONTROLE ET

ACCESSOIRES

Les chaudières RCM sont

équipées des composants

suivants :

-

Jaquette peinte, rapide

à monter après

l’installation du

calorifuge

- Double

isolation

thermique par matelas

en laine de verre

- Plaque

brûleur

- Chambre

de

combustion avec viseur

de flammes et trappe de

ramonage ou

d'inspection anti-chocs

-

Tableau de contrôle et

de régulation de la

chaudière qui

comprend:

un thermomètre

aquastates de

régulation (circulateur –

bruleur)

un aquastat de sécurité.

-

Série de chicanes en

acier inoxydable.

2. MONTAGE

2.1 MONTAGE DE LA

CHAUDIERE

-

La chaudière doit être

placée de façon à

respecter les distances

minimales visées par les

règlements en vigueur.

Notamment par rapport

aux murs du local de

chaufferie pour assurer

un accès aisé pour la

maintenance (Cf.

chapitre 3.8).

-

La chaudière doit être

posée sur un sol

horizontal et calculé en

fonction du poids de la

chaudière pleine d'eau.

-

Les tuyaux qui arrivent

aux raccords de la

chaudière doivent être

soutenus et disposés de

façon à ne créer aucun

effort sur les raccords

de la chaudière.

-

Les raccords des deux

tuyaux souples du

brûleur doivent être

ПРИБОРЫ

И

КОМПЛЕКТУЮЩИЕ

Котлы

серии

RCM

поставляются

со

следующими

компонентами

:

-

панель

управления

,

на

которой

расположены

::

регулирующие

термостаты

(

насоса

и

горелки

)

предохранительный

термостат

с

ручной

перезарядкой

термометр

выключатель

-

углубление

для

тестового

термометра

-

ответный

фланец

для

крепления

горелки

-

слой

керамического

волокна

для

тампонажа

сопла

горелки

-

турбулизаторы

-

контр

фланцы

с

прокладками

и

болтами

(

для

фланцевых

соединений

)

-

слой

стекловаты

для

изоляции

обшивки

-

внешние

панели

2.

МОНТАЖ

2.1

МОНТАЖ

КОТЛА

-

Установить

котел

на

предназначенную

для

него

ровную

площадку

,

обеспечить

постоянную

поддержку

несущей

конструкции

,

размеры

которой

должны

соответствовать

общему

весу

котла

-

Провести

общий

осмотр

(

включая

огнеупорное

покрытие

дверцы

),

для

проверки

,

что

котлу

не

был

нанесен

вред

во

при

транспортировке

.

-

Котел

должен

быть

установлен

с

соблюдением

мин

.

расстояния

до

стен

,

предусмотренного

действующими

правилами

;

доступ

к

котлу

должен

быть

легким

для

Summary of Contents for RCM 105

Page 2: ......