RCM

EDITION 09 / 2002

-

17

-

caldaia, l’impianto deve

essere completato con i

dispositivi previsti dalle

specifiche tecniche

applicative (Raccolta “R”)

del D.M. 1 dicembre 1975 -

Titolo II – riguardante le

norme di sicurezza per

apparecchi contenenti liquidi

caldi sotto pressione

emanato dall’I.S.P.E.S.L. :

-

vaso di espansione

(aperto o chiuso)

-

tubo di sicurezza

-

valvola o valvole di

sicurezza

- manometro

con

rubinetto e flangia per

manometro di controllo

-

pressostato di blocco

-

II termostato di blocco o

valvola di

intercettazione del

combustibile o valvola di

scarico termico.

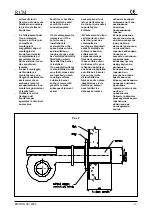

3.3 TUBAZIONI DI

MANDATA E RITORNO

ACQUA DI

RISCALDAMENTO

1.

Si consiglia di collegare

la caldaia alla rete del

riscaldamento con

l'interposizione di due

valvole

d’intercettazione, che

permettono di poter

isolare la caldaia dal

resto dell'impianto.

2.

Le eventuali valvole

d’intercettazione

devono essere disposte

in modo tale che, in

caso di chiusura, non

esclude il tratto di

tubazioni sul quale sono

installati gli organi di

sicurezza (pressostato,

termostato di blocco,

tubo di

sicurezza/valvola di

sicurezza); in ogni caso

il tutto deve

corrispondere a quanto

stabilito dal D.M. 1-12-

75 Racc. R I.S.P.E.S.L.

3.

In fase di progettazione

e d’esecuzione

dell'impianto, evitare

accuratamente di creare

punti nei quali possano

ristagnare bolle d'aria.

Se questa condizione

non può essere

rispettata, prevedere

delle valvole

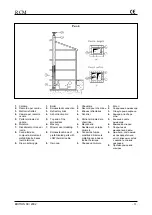

Moreover install the burner

on the burner plate and

connect the gas manifold or

fasten the fuel hoses so that

the door can be opened

without impediments.

Check that the turbulators

are present in the smoke

tubes and that no

processing residue or

foreign matter is present

inside the furnace.

The system must also be

furnished with all devices

required by local codes

regarding hot water boilers.

3.3 HEATING WATER

DELIVERY AND RETURN

PIPELINES

1.

Install two on/off valves

when connecting the

boiler to the heating

system pipeline

network. This makes it

possible to isolate the

boiler from the rest of

the heating system.

2.

On/off valves, when

installed, must be

placed so that they do

not exclude safety

components when they

are activated (pressure

switches, block

thermostat, relief

valve/relief pipeline,

etc.). The entire

installation, in any case,

must correspond to the

suitable installation

regulation

3.

Avoid creating points

where air bubbles can

form and stagnate when

designing and installing

the pipeline system. If

this cannot be avoided

then install automatic air

bleed valves or bleed

pipelines that drain to

the ground and that ave

soupapes de sécurité

est correctement

effectué.

3.3 TUYAUX DE DEPART

ET DE RETOUR DU

CIRCUIT DE CHAUFFAGE

1.

Il est conseillé de

raccorder la chaudière

au réseau du chauffage

en intercalant deux

vannes d’arrêt pour

isoler la chaudière du

reste de l’installation en

cas de besoin.

2.

Les vannes d’arrêt

éventuelles doivent être

disposées de façon

qu’en cas de fermeture,

le tronçon de tuyaux sur

lequel sont installés les

organes de sécurité

(manostat, thermostat

de blocage, tuyau de

sécurité/soupape de

sécurité) ne soit pas

exclu; en tout état de

cause, le tout doit être

conforme aux

règlements et normes

en vigueur

3.

Au cours de la

conception et de

l’exécution de

l’installation, éviter

soigneusement de créer

des contre-pentes où

des bulles d’air puissent

stagner. Prévoir des

purgeurs d’air

automatiques ou des

8.

Проверить

правильное

соединение

дренажа

предохранительных

клапанов

.

3.3

ТРУБОПРОВОД

ПОДАЧИ

И

ВОЗВРАТА

ВОДЫ

ДЛЯ

ОТОПЛЕНИЯ

1.

Рекомендуется

присоединять

котел

к

сети

отопления

с

использованием

двух

отсекающих

клапанов

,

которые

позволят

изолировать

котел

от

остальной

установки

2.

Отсекающие

клапаны

должны

быть

расположены

так

,

чтобы

в

случае

закрытия

они

не

исключали

тот

отрезок

трубопровода

,

на

котором

установлены

предохранительные

компоненты

(

прессостат

,

термостат

блокировки

,

предохранительную

трубу

/

предохранительный

клапан

)

3.

Во

время

проектирования

и

монтажа

установки

избегать

создания

точек

,

в

которых

могут

застаиваться

пузырьки

воздуха

.

Если

это

условие

не

соблюдается

,

необходимо

предусмотреть

два

автоматических

клапана

Summary of Contents for RCM 105

Page 2: ......