9

6.1

Summary of configuration functions

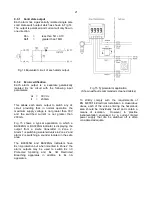

This section summarises each of the main

configuration functions and includes a cross

reference to a more detailed description. Fig 7

illustrates the location of each function within the

configuration menu. The lineariser and the

optional factory fitted alarms are described

separately in sections 7 and 9.3 of this manual.

Display

Summary of function

FunC

Indicator function

Defines the relationship between the

4/20mA input current and the indicator

display. May be set to:

5td

Standard linear relationship

root

Square root extraction

Lin

16 segment adjustable

lineariser – see section 7.

See section 6.2

rESn

Display resolution

Defines the resolution of the least

significant display digit. May be set to

1

,

2

,

5

or

10

digits.

See section 6.3

dP

Decimal point

Positions a dummy decimal point

between any of the digits or turns it off.

See section 6.4

CAL

Calibration of the digital display using

an external current source.

Enables the zero and span of the

indicator to be adjusted using an external

current source such as a calibrator.

When used with an accurate traceable

current source this is the preferred

method of calibration.

See section 6.5

5Et

Calibration of display using internal

references.

Enables the zero and span of the

indicator to be adjusted without the need

for an accurate input current or

disconnection from the 4/20mA loop. See

section 6.6

bAr

Bargraph format and calibration

Only the BA324NG has a bargraph

The bargraph may be conditioned to start

from left, right or centre of the display, or

it may be disabled. When optional

alarms are fitted it can also display both

alarm setpoints and the measured value.

The bargraph may be calibrated to start

and finish at any value within the

indicator’s calibrated digital display.

See section 6.7

Display

Summary of function

C--P

Function of

(

push button

The indicator may be configured to

display the input current in milliamps, or

the input current as a percentage of the

4/20mA input when the

(

push button is

operated in the display mode.

See section 6.8

tArE

Tare function

When enabled the tare function sets the

indicator display to zero when the

)

push button is operated in the display

mode.

See section 6.9

CodE

Security code

Defines a four digit numeric code that

must be entered to gain access to the

configuration menu. Default code

0000

disables this security function and allows

unrestricted access to all conditioning

functions.

See section 6.10

r5Et

Reset

Contains two sub-functions,

ConF

which

returns the indicator to the default

conditions shown in section 6.0 and

LtAb

which returns the lineariser to the default

conditions shown in section 7.3. To

prevent accidental use both resets must

be confirmed by entering

5urE

before

they will be executed.

See section 6.11