25

9.3.10 Alarm silence time:

5iL

This function is primarily intended for use in small

installations where the alarm output directly

operates an alarm annunciator such as a sounder

or beacon. When the alarm silence time, which is

adjustable between 0 and 3600 seconds in 1

second increments, is set to any figure other than

zero, the

(

push button becomes an alarm

accept button. After an alarm has occurred,

operating the

(

button will cause the alarm output

to revert to the non-alarm condition for the

programmed alarm silence time. If the alarm

condition still exists at the end of the silence time,

the alarm output will be reactivated. During the

silence time the indicator alarm annunciator will

flash until the silence time expires or the alarm is

cleared.

If the

FL5H

function, which flashes the indicator

display when an alarm occurs has been enabled, it

will only function when the alarm output is

activated, not during the silence time. See section

9.3.11

To adjust the alarm silence time select

5iL

from

the alarm configuration menu and press

(

which

will reveal the existing silence time. The flashing

digit of the silence time can be adjusted using the

&

and

*

push buttons, and the

(

button to

move control to the other digits. When the

required silence time has been entered press

)

to return to the alarm menu.

9.3.11 Flash display when alarm occurs:

FL5H

In addition to the two alarm annunciators on the

top left hand corner of the indicator display which

show the status of both alarms, this function

provides an even more conspicuous indication that

an alarm condition has occurred.

When enabled, the function alternates the indicator

display between the numerical value and the alarm

reference,

ALr1

or

ALr2

, when the alarm output is

activated. If both alarm outputs are activated, the

alarm references are displayed in sequence.

To enable or disable the function select

FL5H

from

the alarm menu and press

(

which will reveal the

current setting

on

or

oFF

. The function can

changed by pressing the

&

or

*

button followed

by the

)

button to return to the alarm menu.

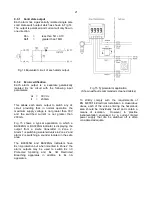

9.3.12 Access setpoint in display mode:

AC5P

This function enables a separate menu providing

access to the alarm setpoints from the display

mode by simultaneously operating the

(

and

*

push buttons. An operator can therefore adjust the

alarm setpoints without having access to the

indicator configuration menu. Protection against

accidental adjustment of the setpoints when the

indicator is in the display mode is provided by a

separate security code.

This direct setpoint access menu is enabled and

the separate security code entered from the

AC5P

function in the alarm configuration menu as shown

in Fig 16. To change the menu parameters select

AC5P

from the configuration menu and press

(

which will display the enable prompt

EnbL

.

Press

(

again to reveal if the direct access menu

is

on

or

oFF

. The

&

or

*

button will toggle the

display between the two conditions.

If

oFF

is selected, the operator will not have access

to the setpoints from the display mode. Return to

the

AC5P

prompt in the main menu by pressing

)

twice.

If

on

is selected, the operator will have direct

access to the alarm setpoints from the display

mode via a separate optional security code. To

define this four digit security code press

(

to

return to the

Enbl

prompt followed by the

&

or

*

button to select the access code prompt

ACCd

.

Pressing

(

will reveal the current security code.

Each digit of the code may be changed by

operating the

&

and

*

push buttons, and the

(

button to move control to the next digit. When the

required code has been entered, press

)

twice to

return to the

AC5P

prompt in the configuration

menu.

Default code

0000

will disable the security code

allowing direct access to the setpoints in the

display mode by pressing the

(

and

*

buttons

simultaneously. Unless otherwise requested new

instruments with alarms are supplied with this

function disabled and the security code set to

0000

.

9.3.13 Adjusting alarm setpoints from the

display mode.

Access to the alarm setpoints from the indicator

display mode is obtained by operating the

(

and

*

push buttons simultaneously as shown in Fig

17. If the setpoints are not protected by a security

code the alarm setpoint prompt

5P1

will be

displayed. If the setpoints are protected by a

security code,

Code

will be displayed first.

Pressing

(

again will enable the alarm security

code to be entered digit by digit using the

&

and

*

buttons to change the flashing digit, and the

(

push button to move control to the next digit. If the

correct code is entered pressing

)

will cause

alarm setpoint prompt

5P1

to be displayed.

Pressing the

&

or

*

button will toggle the

display between the two alarm setpoint prompts

5P1

and

5P2

.

If an incorrect security code is entered, or a button

is not pressed within twenty seconds, the indicator

will automatically return to the display mode.