13

6.10

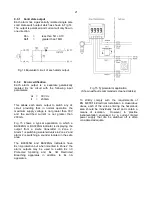

Security code:

CodE

Access to the instrument configuration menu may

be protected by a four digit security code which

must be entered to gain access. New instruments

are configured with the default security code

0000

which allows unrestricted access to all

configuration functions.

To enter a new security code select

CodE

from the

configuration menu and press

(

which will cause

the indicator to display the existing security code

with one digit flashing. The flashing digit can be

adjusted using the

&

or

*

push buttons, when

set as required operating the

(

button will

transfer control to the next digit. When all the

digits have been adjusted press

)

to return to the

CodE

prompt in the configuration menu. The

revised security code will be activated when the

indicator is returned to the display mode. Please

contact BEKA associates sales department if the

security code is lost.

6.11

Reset to factory defaults:

r5Et

This function enables the indicator and the

lineariser to be quickly returned to the factory

default configurations shown in sections 6.0 and

7.3

To reset the indicator or lineariser select

r5Et

from

the configuration menu and press

(

, the indicator

will display one of the reset options

ConF

or

LtAb

.

ConF

Resets the indicator to defaults

LtAb

Resets the lineariser to defaults

Using the

&

or

*

push button select the required

sub-function and press

(

. To prevent accidental

resetting the request must be confirmed by

entering

5urE

. Using the

*

button set the first

flashing digit to

5

and press

(

to transfer control

to the second digit which should be set to

u

.

When

5urE

has been entered pressing the

)

button will reset the selected configuration menus

and return the display to the

r5Et

function in the

configuration menu.

6.12

Under and over-range

If the numerical display range of the indicator is

exceeded, all the decimal points will flash as

shown below:

BA304NG

BA324NG

Underrange

-9

.

9

.

9

.

9

-9

.

9

.

9

.

9

.

9

Overrange

9

.

9

.

9

.

9

9

.

9

.

9

.

9

.

9

Although not guaranteed, most indicators will

continue to function normally with an input current

between 1.8mA and 4mA, at lower currents the

instrument will display

LPLo

before it stops

functioning.

Under or over-range of the BA324NG bargraph is

indicated by a flashing arrow at the appropriate

end of the bargraph.