8

Fig 6b Inserting scale card into the

instrument assembly.

6.

CONFIGURATION AND CALIBRATION

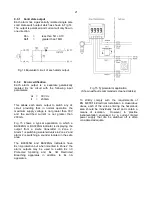

Both indicators are configured and calibrated via

the four front panel push buttons. All the

configuration functions are contained in an easy to

use intuitive menu that is shown diagrammatically

in Fig 7.

Each menu function is summarised in section 6.1

and includes a reference to more detailed

information. When the indicator is fitted with

alarms additional functions are added to the menu

which are described in section 9.3

Throughout this manual push buttons are shown

as

(

,

)

,

&

or

*

, and legends displayed by

the indicator are shown within inverted commas

e.g.

CAL

and

ALr2

.

Access to the configuration menu is obtained by

operating the

(

and

)

push buttons

simultaneously. If the indicator security code is set

to the default

0000

the first parameter

FunC

will be

displayed. If a security code other than the default

code

0000

has already been entered, the indicator

will display

CodE

. Pressing the

(

button will clear

this prompt allowing each digit of the code to be

entered using the

&

and

*

push buttons and the

(

button to move control to the next digit. When

the correct four digit code has been entered

pressing

)

will cause the first parameter

FunC

to

be displayed. If the code is incorrect, or a button

is not pressed within twenty seconds, the indicator

will automatically return to the display mode.

Once within the configuration menu the required

parameter can be reached by scrolling through the

menu using the

&

and

*

push buttons as shown

in Fig 7. When returning to the display mode

following recalibration or a change to any function,

the indicator will display

dAtA

followed by

5AVE

while the new information is stored in permanent

memory.

All new indicators are supplied calibrated as

requested at the time of ordering. If calibration is

not requested, indicators will be supplied with the

following default configuration:

Default Configuration

BA304NG BA324NG

Access code

CodE

0000

0000

Function

FunC

Linear

Linear

Display at 4mA

2ero

0.0

0.00

Display at 20mA

5PAn

100.0

100.00

Resolution

rE5n

1 digit

1 digit

Bargraph start

BarLo

-----

0.00

Bargraph finish

BarHi

-----

100.00

(

button in display mode

C--P

%

%

Tare

tArE

Off

Off