17

To add a break-point using the

&

or

*

button

select

5Et

from the configuration menu and press

(

which will result in the

Add

sub-function prompt

being displayed. To enter the sub-function press

(

which will reveal the current break-point and

the total number of break-points which have

already been entered. When adding a break-point

the insertion position can be selected using the

&

and

*

push buttons followed by

(

push button

to insert the additional break-point. In previously

uncalibrated linearisers each new break-point

should be added in front of the highest existing

break-point, if this sequence is not followed a

FaiL

message will occur when the breakpoints are

calibrated. See example in section 7.2.1.

The delete break-point, sub-function

dEL

operates

in exactly the same way as the

Add

sub-function

described above. Once within the

dEL

function

each time the

(

button is pressed a break-point is

removed. When deleting a break-point from a

calibrated indicator, the break-point to be deleted

can be selected using the

&

and

*

push

buttons. The minimum number of break-point is 2,

break-points

0

:1

and

1

:1

.

When the required number of linearising break-

point has been entered, return to the linearisation

sub-menu by pressing

)

. The indicator will

display the

Add

or

dEL

prompt depending upon the

last sub-function used. The indicator input current

and corresponding indicator display at each break-

point, which is the segment finishing point as

shown in Fig 9, can now be entered using the

in

and

di5P

sub-functions.

Using the

&

or

*

button select

in

from the sub-

menu and press

(

which will reveal the starting

point for the first segment

0

:

n

, where n is the total

number of break-point entered. Press

(

and use

the

&

and

*

buttons and the

(

button to move

between digits, to enter the input current in

milliamps at which the first break-point is required,

usually 4.000mA. When set as required, press

)

to return to the

0

:

n

prompt from which the next

break-point can be selected using the

&

and

*

buttons. When the required break-point has been

selected press

(

and enter the indicator input

current at which this break-point is required using

the

&

and

*

buttons and the

(

button to move

between digits. Repeat this procedure until the

indicator input current at all the break-points has

been defined and then return to the

in

sub-function

by pressing the

)

button.

The corresponding indicator display at each of the

break-points can now be defined using the

di5P

sub-function. Using the

&

and

*

buttons select

the

di5P

sub-function and press

(

which will

reveal the starting point for the first break-point

0

:

n

,

where

n

is the total number of break-points

entered.

Press

(

and use the

&

and

*

buttons and the

(

button to move between digits, to enter the

required indicator display at the first break-point.

When set as required, press

)

to return to the

0

:

n

prompt from which the next break-point can be

selected using the

&

or

*

buttons. When the

required break-point has been selected press

(

and set the required indicator display at this

break-point.

Repeat this procedure until the indicator display at

all the break-points has been defined and then

return to the

5Et

function in the configuration menu

by pressing the

)

button twice.

Error message

If during calibration the indicator displays

a

FAiL

error message the current at which

the selected break-point is being set is not

above the proceeding break-point or is not

below the following break-point.

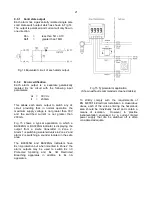

7.2.1

Example

Adding break-points to a new indicator

When adding break-points to a new indicator, or to

a lineariser following resetting to the factory

defaults using the

LtAb

function described in

section 6.11, each additional break-point should be

added before the highest existing breakpoint.

The first additional break-point should be added

before the default break-point

1

:1

which will result

in a display of

1

:

2

. If more new break-points are

required, using the

*

button select the new

highest break-point

2

:

2

and add the second

additional break-point by operating the

(

push

button which will result in a display of

2

:

3

. Repeat

the sequence until the required number of break-

points has been entered.

7.3

Under and over-range

The lineariser does not change the under and

over-range indication described in section 6.12. At

input currents below that specified for the first

break-point

0

:

n

, the indicator will continue to use

the specified slope of the first segment.

At input currents above that specified for the last

break-point

n

:

n

, the indicator will continue to use

the slope specified for the last lineariser segment.

7.4

Lineariser default configuration

When the lineariser is reset to the factory defaults

using the

LtAb

function described in section 6.11,

the defaults conditions are:

Indicator display

BA304NG BA324NG

First break-point

0

:1

4mA

0.0

0.00

Second break-point

1

:1

20mA 100.0

100.00