24

9.3.4

Alarm enable:

EnbL

This function allows each alarm to be enabled or

disabled without altering any of the alarm

parameters. To enable or disable the alarm select

EnbL

from the alarm menu and press

(

which will

reveal the current setting

on

or

oFF

. The function

can be changed by pressing the

&

or

*

button

followed by the

)

button to return to the alarm

menu.

9.3.5

Setpoint adjustment:

5P1

and

5P2

The setpoint of each alarm may be positioned

anywhere in the numerical display of the indicator

providing that this corresponds to an input current

between 3.8 and 20.2mA. e.g. If the indicator has

been calibrated to display 0 with 4mA input and

10000 with 20mA input, the two alarm setpoints

may be positioned anywhere between -125 and

10125.

To adjust the setpoint select

5P1

or

5P2

from the

alarm configuration menu and press

(

which will

reveal the existing alarm setpoint. The flashing

digit of the setpoint can be adjusted using the

&

and

*

push-buttons, and the

(

button to move

control to the next digit. When the required

setpoint has been entered press

)

to return to

the alarm configuration menu.

The alarm setpoints may also be adjusted when

the indicator is in the display mode, see section

9.3.12.

9.3.6

Alarm function:

Hi

.

Lo

Each alarm can be independently conditioned as a

high alarm or as a low alarm. To check or change

the alarm function select

Hi

.

Lo

from the alarm

menu and press

(

to reveal the current setting.

The function can be changed by pressing the

&

or

*

button followed by the

)

button to return to

the alarm menu.

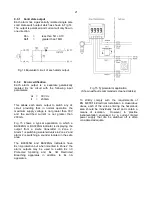

9.3.7

Alarm output status:

no

.

nC

Configures the solid state alarm output to be open

‘no’ or to be closed

nC

in the non-alarm condition.

When deciding which is required, care should be

taken to ensure that the alarm output is fail safe as

illustrated in Fig 13.

no

Alarm output open in non-alarm condition

nC

Alarm output closed in non-alarm condition

CAUTION

When the 4/20mA supply is removed from

the loop powered indicator, both alarm

outputs will open irrespective of

conditioning. Therefore for fail safe

operation both alarm outputs should be

conditioned to be open in the alarm

condition

nC

.

To check or change the alarm output status, select

no

.

nC

from the alarm configuration menu and press

(

to reveal the setting. The function may be

changed by pressing the

&

or

*

button followed

by the

)

button to return to the alarm

configuration menu.

9.3.8

Hysteresis:

H5tr

Hysteresis is shown in the units that the indicator

has been calibrated to display.

To adjust the hysteresis select

H5tr

from the alarm

menu and press

(

which will reveal the existing

figure. The flashing digit can be adjusted using

the

&

and

*

push-buttons, and the

(

button

will move control to the next digit. When the

required hystersis has been entered press

)

to

return to the alarm configuration menu.

e.g. An indicator calibrated to display 0 to 10000,

with a high alarm set at 9000 and hysteresis of 200

will perform as follows:

The high alarm will be activated when increasing

indicator display equals 9000, but will not reset

until the indicator display falls below 8800.

9.3.9

Alarm delay:

dELA

This function delays activation of the alarm output

for an adjustable time following the alarm condition

occurring. The delay can be set in 1 second

increments between 0 and 3600 seconds. If a

delay is not required zero should be entered. To

adjust the delay select

dELA

from the alarm

configuration menu and press

(

which will reveal

the existing delay. The flashing digit of the delay

can be adjusted using the

&

and

*

push

buttons, and the

(

button to move control to the

other digits. When the required delay has been

entered press

)

to return to the alarm menu.

e.g. An indicator with a high alarm set at 9000 and

an alarm delay of 30 seconds will perform as

follows:

The alarm annunciator will start to flash when an

increasing indicator display equals 9000, but the

alarm output will not be activated until the alarm

condition has existed continuously for 30 seconds.

When the alarm output is activated, the alarm

annunciator will stop flashing and be permanently

activated.

If the

FL5H

function, which flashes the indicator

display when an alarm occurs, has been enabled,

it will not start to function until the alarm output is

activated.

See section 9.3.11