27

9.4 Pipe mounting kit

The BA393G is a 316 stainless steel kit which will

fix either indicator to a horizontal or vertical pipe

with an outside diameter between 40 and 73mm.

Detailed assembly instructions are supplied with

each BA393G pipe mounting kit.

9.5 Panel mounting kits

Two alternative panel mounting kits are available

for the BA304NG and BA324NG indicators.

The BA394G kit consists of two 316 stainless steel

brackets which secure an indicator into a panel

aperture. The kit does not seal the joint between

the panel and the instrument and it is intended for

mounting an indicator onto an open panel.

The BA494G panel mounting kit is manufactured

from the same carbon loaded GRP material as the

indicator enclosure. It provides an IP66 seal

between the instrument panel and the indicator

and is therefore suitable for mounting a BA304NG

or a BA324NG in a sealed panel enclosure.

However, although the BA494G has ATEX and

IECEx intrinsic safety certification,

the BA494G

does not have formal Ex nA and Ex tc

certification

.

Detailed assembly instructions are supplied with

each panel mounting kit.

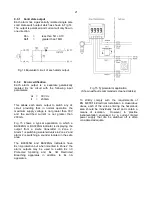

9.6

Back-box terminal assembly

If it is necessary to terminate the field wiring prior

to the installation of the indicator display, a back-

box terminal assembly is available as a factory

fitted option. This accessory includes terminals for

the field wiring and diodes which maintain the

continuity of the 4/20mA loop when the indicator

display is unplugged.

When the indicator display is unplugged from the

back-box, the voltage drop introduced into the

4/20mA loop by the instrument increases to 5V. If

an optional backlight is fitted and connected for

loop powering, the voltage drop increases to 11.5V

when the indicator display is unplugged. This

voltage drop can be reduced to 7.5V by connecting

a 7.5V Zener diode with a minimum rating of 1.3W

at 25ºC (BZX85 or 1N5343) between terminals 3

(diode cathode) and 12.(diode anode).

The optional terminal assembly also includes

additional terminals which may be used for linking

cable screens and two terminals connected to the

carbon loaded GRP enclosure. If the enclosure is

not fixed to an earthed structure, one of these

terminals or the earth terminal on the bonding plate

should be connected to the plant's potential

equalising conductor.

Fig 19 Optional back-box terminal assembly