6

4.2

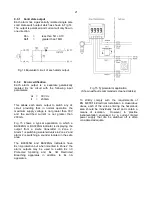

Remote indication

The BA304NG and the BA324NG may be driven

directly from a safe area instrument with a 4/20mA

output to provide a remote display within a Zone 2

hazardous area.

There are four design requirements:

1. The current flowing in the 4/20mA loop, must

not exceed 100mA in normal operation.

2.

Wiring must comply with Clause 9 of

EN60079-14

Electrical installation in

hazardous areas

.

3. The instrument enclosure must be fitted with

Ex n or Ex e certified glands, conduit fittings

or blanking plugs.

4. The safe area 4/20mA output from the safe

area instrument must be able to supply the

1.2V required to operate the indicator. This

increases to 5.0V if the indicator includes an

optional loop powered backlight. See 9.4.1

Fig 3 shows a typical application.

Fig 3 Remote indication in Zone 2 hazardous area

To strictly comply with the requirements of

EN 60079:14

Electrical Installation in Hazardous

Areas

, each of the wires entering the hazardous

area should be individually fused and contain a

means of isolation. However, in practice

instrumentation energised by a current limited

power supply or instrument that can be switched

off is often considered adequate.

5.

INSTALLATION

5.1

Location

The BA304NG and BA324NG indicators are

housed in robust IP66 glass reinforced polyester

(GRP) enclosures incorporating an armoured glass

window and stainless steel fittings making them

suitable for exterior mounting in most industrial

on-shore and off-shore Zone 2 installations. The

indicators should be positioned where the display

is not in continuous direct sunlight.

Field wiring terminals are located on the rear of the

indicator assembly as shown in Fig 5. If the field

wiring is to be terminated prior to the installation of

the indicator assembly, a back-box terminal

assembly, which includes a 4/20mA continuity

diode and additional terminals for linking cable

screens is available as an option. See section 9.5

of this manual.

Indicator terminals 2 and 4 are internally joined and

may be used for linking the return 4/20mA wire -

see Fig 2.

The instrument back-box is supplied with a

bonding plate that may be mounted on the inside

or outside of the enclosure to ensure electrical

continuity between the two conduit or cable entries.

The bonding plate includes an M4 earth stud

which, if the enclosure is not bolted to an earthed

post or structure, should be connected to the plant

potential equalising conductor.

An insulated M4 stud is provided in the bottom

right hand corner the back-box for interconnecting

cable screens.

Both indicators are surface mounting, but may be

pipe mounted using one of the accessory kit

described in section 9.4 of this manual.

5.2

Installation Procedure

Fig 4 illustrates the instrument installation

procedure.

A. Remove the indicator assembly by

unscrewing the four captive 'A' screws.

B. Mount the enclosure back-box on a flat

surface and secure with screws or bolts

through the four 'B' holes. Alternatively use

one of the pipe mounting kits described in

section 9.4.

C. Remove the temporary hole plug and install

an appropriate IP and temperature rated

cable gland or conduit fitting. If two entries

are required, the IP66 stopping plug should

be replaced with an appropriate IP and

temperature rated cable gland or conduit

fitting.

D. Connect the field wiring to the terminals as

shown in Fig 5. Replace the instrument

assembly on the back-box and evenly tighten

the four 'A' screws.