20

9.2.2

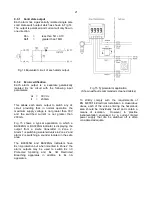

Separately powering the backlight

The optional backlight may also be powered from a

separate safe area power supply as shown in

Fig 12.

Fig 12 Backlight separately powered

The separately powered backlight is a current sink

which will draw a constant 34.7mA when the

supply voltage is equal to or greater than 11V. At

lower supply voltages the backlight will continue to

function but with reduced brilliance.

The ATEX certificate therefore only specifies the

maximum safety input voltage Ui for terminals 12

and 14.

Ui

=

30V

To strictly comply with the requirements of

EN 60079:14

Electrical Installation in Hazardous

Areas

, each of the wires entering the hazardous

area should be individually fused and contain a

means of isolation. However, in practice

instrumentation energised by a current limited

power supply that can be switched off is often

considered adequate.

9.3

Alarms

CAUTION

These alarms outputs should not be used

for critical safety applications such as an

emergency shut down system.

Both models can be supplied with factory fitted

dual solid state, single pole alarm outputs. Each

alarm output may be independently conditioned as

a high or low alarm with a normally open or

normally closed output in the non-alarm condition.

When the 4/20mA current powering the indicator is

removed both alarm outputs will open irrespective

of configuration. The open circuit condition should

therefore be chosen as the alarm condition when

designing an alarm system. Fig 13 illustrates the

conditions available and shows which are fail safe.

When an alarm occurs an alarm annunciator on

the indicator front panel is activated and if required

the numerical display can alternate between the

measured value and the alarm channel

identification

ALr1

or

ALr2

.

CAUTION

The alarms are activated by the indicator’s

numerical display. Use of the Tare

Function

tArE

will change the numerical

display, the alarms will continue to

function at the original displayed value,

but this will correspond to a different input

current.

Fig 13 Alarm outputs

Configurable functions for each alarm include

adjustable setpoint, hysteresis, alarm delay and

alarm accept.