53

53

Too fast advance

Wrong cutting speed

Wrong tooth pitch

Ineffective gripping of the

part in the vice.

Blade touching material

at beginning of cut

smooth and even when sliding

between the blade guide pads.

Decrease advance, exerting less

cutting pressure. Adjust the braking

device.

Change speed and/or type of blade.

Choose a suitable blade.

Check and reposition the piece part.

At the beginning of the cutting process,

never lower the saw bow before

starting the blade motor.

Blade guide pads not

maintained or dirty

because of lack of

maintenance

Blade guide block too far

from material to be cut

Improper position of

blade on flywheels

Insufficient or incorrect

lubricating coolant

Check distance between pads.

Extremely close guiding may cause

cracks and breakage of the tooth. Use

extreme care when cleaning.

Position head as near as possible to

material to be cut so that only the

blade section employed in the cut is

free, this will prevent deflections that

would excessively stress the blade.

The back of blade rubs against the

support due to deformed or poorly

welded bands causing cracks and

swelling of the back contour.

Check level of liquid in the tank.

Increase the flow of lubricating coolant

checking that the hole and the liquid

outlet pipe are not blocked.

STREAKED OR ETCHED

BANDS

Damaged or chipped

blade guide pads

Tight or slackened blade

guide bearings.

Replace them.

Adjust them (see machine adjustments

section).

CUTS OFF THE

Blade not parallel to the

Check location of the blade guide

Summary of Contents for BS-350SA

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 18: ...15 15 GETTING TO KNOW YOUR MACHINE I H G F E D C B A T P O Q S M N U L R V J K T...

Page 36: ...33 33...

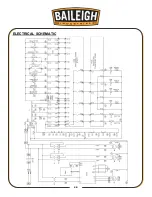

Page 49: ...46 46 ELECTRICAL SCHEMATIC...

Page 58: ...55 55 NOTES...

Page 59: ...56 56 NOTES...