52

52

shape

Insufficient or incorrect

lubricating

coolant.

Teeth positioned in the

direction

opposite the cutting

direction.

one. Adjust blade guide pads.

Check level of liquid in the tank.

Increase the flow of lubricating coolant

checking that the hole and the liquid

outlet pipe are not blocked. Check the

emulsion percentage.

Turn teeth to correct direction. (The

blade needs to be turned inside out.)

PREMATURE BLADE

WEAR

Faulty running-in of blade

Teeth positioned in the

direction opposite the

cutting direction

Poor quality blade

Too fast advance

Wrong cutting speed

Defects on the material

or material too hard

Insufficient or incorrect

lubricating coolant.

Use slow speeds when making first

few cuts. Generously spray the cutting

area with lubricating coolant.

Turn teeth to correct direction. (The

Blade needs to be turned inside out.)

Use a superior quality blade.

Decrease advance, exerting less

cutting pressure. Adjust the braking

device.

Change speed and/or type of blade.

Material surfaces can be oxidized or

covered with impurities making them

harder that the blade itself. Avoid

cutting these materials and remove

any such impurities as quickly as

possible.

Check level of liquid in the tank.

Increase the flow of lubricating coolant

checking that the hole and the liquid

outlet pipe are not blocked. Check the

emulsion percentage.

BLADE BREAKAGE

Faulty welding of blade

The meeting surfaces must perfectly

match and once they are welded, they

must have no inclusions or bubbles;

the welded blade must be perfectly

Summary of Contents for BS-350SA

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 18: ...15 15 GETTING TO KNOW YOUR MACHINE I H G F E D C B A T P O Q S M N U L R V J K T...

Page 36: ...33 33...

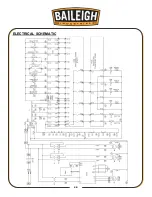

Page 49: ...46 46 ELECTRICAL SCHEMATIC...

Page 58: ...55 55 NOTES...

Page 59: ...56 56 NOTES...