16

16

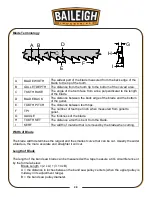

A

Vise Hand Wheel

Turning hand-wheel opens and closes the vise for course

adjustment to within .5” to .75” (12.7 – 19mm) of clamping

the material.

B

Vise Clamping Cylinder

During normal operation, hydraulic pressure will extend the

cylinder to clamp the material for the cut. After the cut, the

vise will open automatically,

C

Vise

Holds front and rear jaws for clamping

D

Blade Tension Hand

Wheel

For applying and releasing blade tension

E

Blade Tension Gauge

Reads tension in Kgs/cm2. For this saw the blade tension

should be 140Kgs/cm2

F

Blade Break Microswitch Shuts down saw if blade breaks or if the tension is too low.

G

Front Blade Guide

Assembly

Guides the blade into the material during the cut. This

guide is adjustable and should be set as close to the

material without interfering with the material.

H

Back Blade Guide

Assembly

This guide is a fixed position and is intended to guide the

blade as it exits the cut path.

I

Control Box

Houses the operator controls

J

Bow Cylinder

The cylinder is used to provide the down and up force to

lower and lift saw bow.

K

Saw Bow Limit Switches.

The limit switches which control the down travel and the up

travel of the saw bow. The down limit switch has limited

adjustment to stop the down travel when the blade has

completed the cut. The up-limit switch has adjustment to

allow the bow to raise about 1: (25mm) above the table to

the full up position as desired.

L

Motor/Gearbox

Drives the saw blade

M

Coolant Pump

Recirculates blade coolant to the blade cutting area.

N

Hydraulic System

The reservoir, motor, pump, and valve assembly which

supplies and controls the hydraulics to operate the

clamping and saw bow cylinders.

O

Miter Lock Lever

Tightens and loosens the saw head to allow the head to

swivel to the desired angle.

P

Angle Indicator

Shows angular cutting degrees. 0 - 60°R, 0 - 45°L

Q

Saw Stand

Supports the saw assembly.

R

Vise Slide Lock

Locks vise in the table slideway. Used with the Track Lock.

S

Flow Regulator

This flow control will allow control of the speed that the ow

descends into and through the cut.

T

E-Stop (Emergency Stop) Shuts down saw in emergency situation

U

Track Lock

Allows vise to slide in track. Used with the Vise Slide Lock.

Summary of Contents for BS-350SA

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 18: ...15 15 GETTING TO KNOW YOUR MACHINE I H G F E D C B A T P O Q S M N U L R V J K T...

Page 36: ...33 33...

Page 49: ...46 46 ELECTRICAL SCHEMATIC...

Page 58: ...55 55 NOTES...

Page 59: ...56 56 NOTES...