44

44

Oil Disposal

Used oil products must be disposed of in a proper manner following your local regulations.

Accessing and Cleaning the Coolant System

•

Clean the drain screens on the machine base and the drains on the ends of the table.

•

Drain and wash out the dirt and debris from the reservoir.

•

Thoroughly clean the pump and pump inlet.

•

Fill the tank with coolant solution.

Coolant System Maintenance

1. Disconnect the saw from the power supply.

2. To clean the tank, first remove the vinyl hose (A) from the

strainer basket.

3. Remove the strainer basket and lift the cover off of the

tank

4. Use a hex wrench to remove the drain plug from the tank

to allow the coolant to drain out.

5. Use a hydraulic vacuum to remove any chips and debris.

6. Thoroughly clean the pump and pump inlet.

7. Replace the drain plug.

8. Fill the tank with coolant to the full mark on the sight

gauge (B)

9. Replace the cover on the tank

10. Drop in the strainer basket and reinsert the vinyl hose.

Oils for Lubricating Coolant

Any 10:1 (water to coolant) solution will work, however we recommend Baileigh Coolant 20:1

(water to coolant) biodegradable metal cutting fluid. It has excellent cooling and heat transfer

characteristics, is non-flammable, and extends tool and machine life. Each gallon of concentrate

makes 21 gallons of coolant.

A

B

Summary of Contents for BS-350SA

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 18: ...15 15 GETTING TO KNOW YOUR MACHINE I H G F E D C B A T P O Q S M N U L R V J K T...

Page 36: ...33 33...

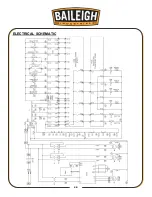

Page 49: ...46 46 ELECTRICAL SCHEMATIC...

Page 58: ...55 55 NOTES...

Page 59: ...56 56 NOTES...