48

48

TROUBLESHOOTING

Electrical Components Diagnosis

1. No Power

Blown fuse

If a fuse is blown, check the related

components for an over-load or short-circuit.

A. No operation on

single-phase

Check the power supply and fuses No. FU4,

FU5 for normal condition.

B. No DC24V (The white

indicator light on the

panel does not light)

Check the transformer’s inputs FU1 and FU2

(1.6A) for normal condition.

Check fuse FU1 (1A) on PCB1 for normal

condition.

C. No DC5V (The rest of

indicator lights are failed.)

Check the transformer’s inputs FU1 and FU2

(1.6A) for normal condition.

Check fuse FU2 (1A) on PCB1 for normal

condition.

D. No AC24V power

Check the transformer’s inputs FU1 and FU2

(1.6A) for normal condition.

Check fuse FU3 (6A) on the distributor board

for normal condition.

Check the connection points of the safety limit

switches at their locations on the machine for

normal condition

-refer to the wire diagram No: WT/M3/C-01,

connection wire No. 4, 5, 6, 7, 8, 19, and 20.

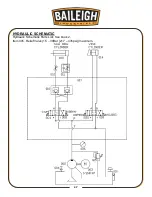

2. Hydraulic pump Failure

Check on hydraulic motor M1 and see if it

works.

Check the pump for normal condition.

Check AC contactor K1 for normal condition

or over-load (FS1).

Check the distributor board for voltage flow to

Coil K1 (Wire No. 9 and 15).

Pump works, but low

pressure

Check the hydraulic flow for normal condition

No contamination, lack of fluid, or leaking.

3. Saw bow

No operation

Check the hydraulic pump.

Check the hydraulic flow for normal condition.

Check the distributor board for voltage flow to

Coil K1 (Wire No. 9 and 15).

Check the signal of the hydraulic magnetic

WARNING:

Make sure the electrical disconnect is OFF before working on

the machine.

Summary of Contents for BS-350SA

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 18: ...15 15 GETTING TO KNOW YOUR MACHINE I H G F E D C B A T P O Q S M N U L R V J K T...

Page 36: ...33 33...

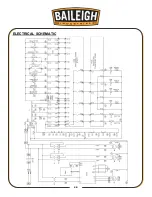

Page 49: ...46 46 ELECTRICAL SCHEMATIC...

Page 58: ...55 55 NOTES...

Page 59: ...56 56 NOTES...