4 - 16

Adjustment

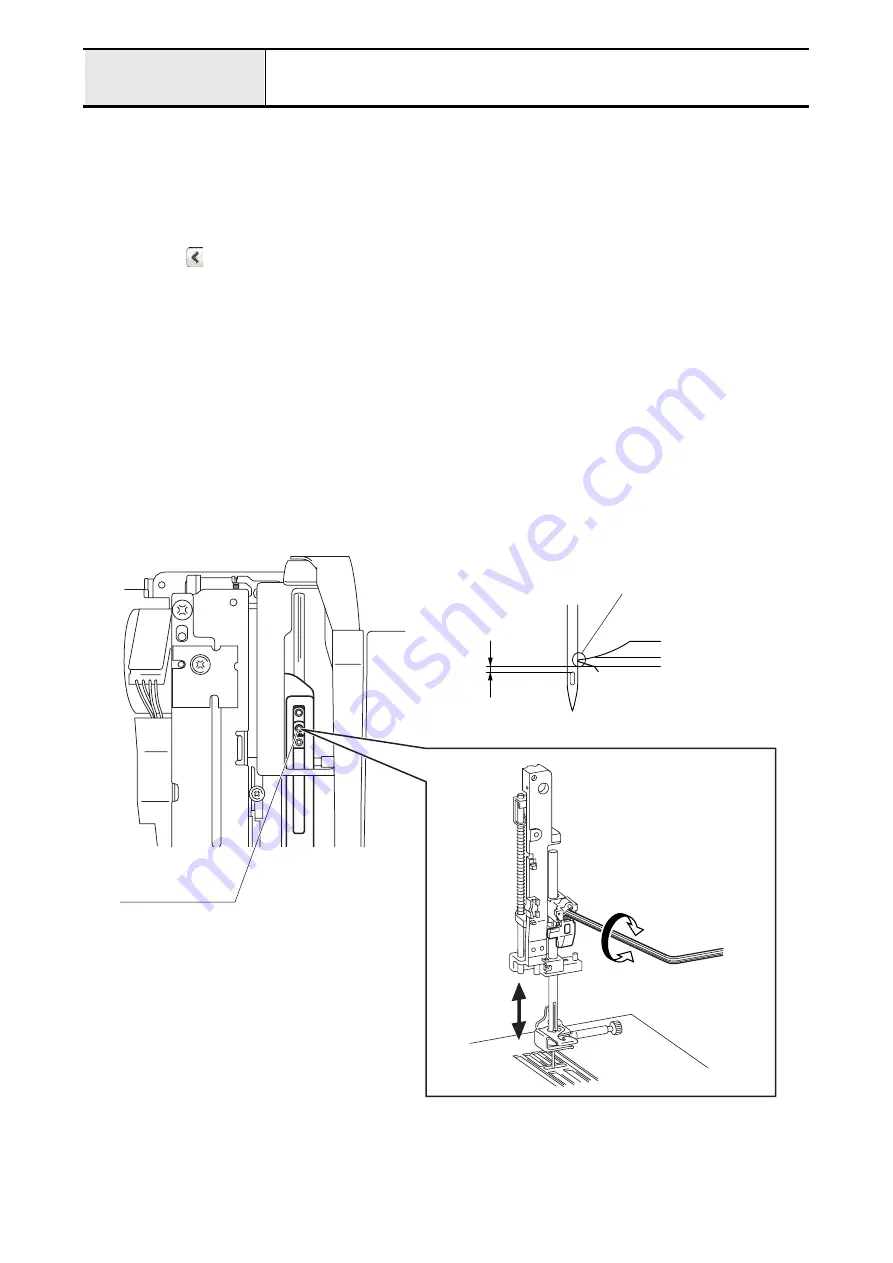

Needle bar height

[Adjustment standard]

When turn the pulley by hand until the right edge of the needle aligns with the outer rotary hook point, clearance

between the top of needle hole and the outer rotary hook point is 1.0 to 1.4mm.

[Adjustment procedure]

1. Start the test mode, and then select the “04” (3-point needle drop mode).

2. Press the

button, then needle move to the left, and turn the power off.

3. Remove the face plate assy..

4. Remove the presser foot, the needle plate B and the needle plate A, and then remove the inner rotary hook assy..

5. Attach the #11 needle.

6. Turn the pulley by hand until the right edge of the needle aligns with the outer rotary hook point.

7. Loosen the socket set screw (CP, M4x4) of the needle bar block.

8. Move the needle bar up and down, and adjust clearance between the top of the needle hole and the outer rotary

hook point is 1.0 to 1.4mm.

*Note

• Check the socket set screw (CP, M4x4) faces front.

9. Tighten the socket set screw (CP, M4x4) of the needle bar block. (tightening torque: 0.78 to 1.18N· m)

*Key point

• Need to adjust “4-18 Needle threader” after this adjustment.

1.0 - 1.4mm

Right edge of needle

and hook point aligns

Socket set screw

(CP, M4x4)

34

Summary of Contents for Ellisimo BLSO

Page 1: ...3...

Page 2: ...xvi 4...

Page 29: ...31...

Page 35: ...Tacony Corp 10 2008 2 3 In the case that the parts separate please assemble as shown 37...

Page 37: ...39...

Page 55: ...4 35 Camera calibration 57...

Page 65: ...67...