CRANE

CO.

280

N.

MIDLAND

AVE.,

STE

258,

SADDLE

BROOK,

NJ

07663

WWW.AVIDCONTROLS.COM

12/17/12

TECH-440/D.W.O. 23135

Page 38 of 55

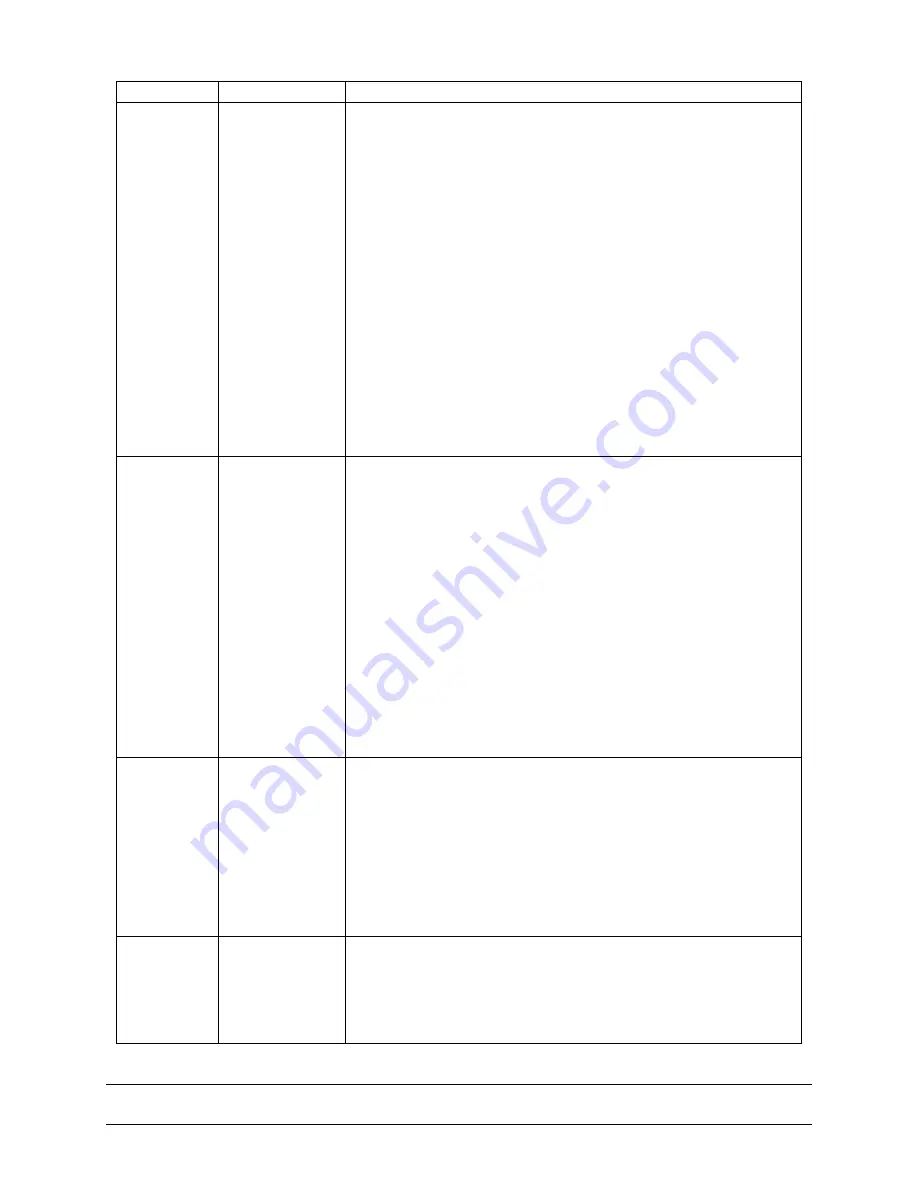

Message Meaning Solution

PWM

overflow

During

calibration an

error occurred

with the PWM

signal that

control the

spool-valve

driver and the

position is not

following the

control signal

Check:

Hall sensor connector and cable, especially if remote (see

Figure 3-4, connector J8)

Magnet assembly is in correct position.

o

For rotary magnets check if it is not rotated 90

degrees (see figures 3.2, 3.3 and 3.4).

o

For linear magnets, check if the magnet assembly

center is matching the actuator mid position (see

figures 3.5, 3.6 and 3.7). Check if the proper fail-down

or fail-up magnet is being used (figure 5.1)

Check if the cable between the inner canister and the

pneumatic transducer assembly is tightly connected

Check the cable and connector between the transducer board

and the spool-valve coil.

Try to replace the Hall sensor and/or the magnet

Remove power for at least 1 minute and retry

Remove power for at least 1 minute, perform a factory default

(see Appendix I) and retry a full auto CAL

Call factory for additional support

HALL

sensor out

of range

(SEN, LO, HI, T)

Hall sensor

used to read

position is

unstable

Check:

Hall sensor connector and cable, especially if remote (see

Figure 3-4, connector J8)

Magnet assembly. For rotary magnets check if it is not rotated

90 degrees (see figures 3.2, 3.3 and 3.4). For linear magnets,

check if the magnet assembly center is matching the actuator

mid position (see figures 3.5, 3.6 and 3.7)

Remove power for at least 1 minute, perform a factory default

(see Appendix I) and retry the calibration

Grounding issues, cable shield is grounded properly,

positioner ground is properly connected to a clean ground

reference.

Sources of electromagnetic noise too close to the sensor or to

the positioner cables, like AC cables for motors, inverters etc

Try to replace the Hall sensor and/or the magnet

Call factory for additional support

mA input

A/D is not in

linear range

An invalid loop

current is

applied during

set-point

calibration

Check:

Check if the current generator is set at the proper value

(between 3.8mA and 20.5mA)

Check the set-point value on the LCD and adjust the current

generator accordingly

Make sure the minimum loop current span is at least 1.6mA

Remove power for at least 1 minute, perform a factory default

(see Appendix I) and retry a full auto CAL

Call factory for additional support

Illegal

calibration

code

An unknown

error has

occurred during

calibration

Check:

Remove power for at least 1 minute and retry

Remove power for at least 1 minute, perform a factory default

(see Appendix I) and retry a full auto CAL

Call factory for additional support