54

Power transmission

M

Safety valve

In the event of a breakdown, this means that

the vehicle can be towed without the engine

running and with the axle raised off the

ground.

Torque is developed at the coupling depen-

ding on the driving situation.

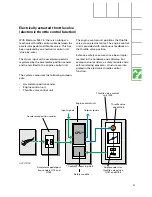

Pressure modulation is induced by means of

the control valve (hydraulic proportional

valve), whose opening cross-section is altered

by a slide valve.

The slide valve is activated by a rack and a

stepping motor.

The control unit together with its software are

located in the immediate vicinity of the step-

ping motor.

A safety valve opens at very higher inner pres-

sure to prevent the coupling from being

damaged.

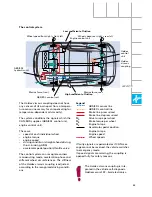

The hydraulics

Torque is transmitted to the rear axle drive by

means of the plate coupling .

The necessary coupling pressure is generated

via the two annular piston pumps. The annu-

lar piston (also known as axial piston) is

driven by an axial piston pump.

The speed at which this pump rotates is the

difference between coupling input and output

speeds.

An even pressure curve is ensured by three

phase-shifted pump strokes.

The annular pistons runs in floating bearings.

They are driven by the pressure generated by

the pre-pressurising pump (an electrically

driven gear pump).

The pre-pressurising pump only operates if

the ignition has been turned on and engine

speed is greater than 460 rpm.

SSP207/12

Two parallel annular

piston pumps

Pre-pressurising

pump

Control valve

Oil filling

Working piston

Plate set

Cam disc

Input

Output