SECTION 2

INSTALLING PRINTER

11

8.

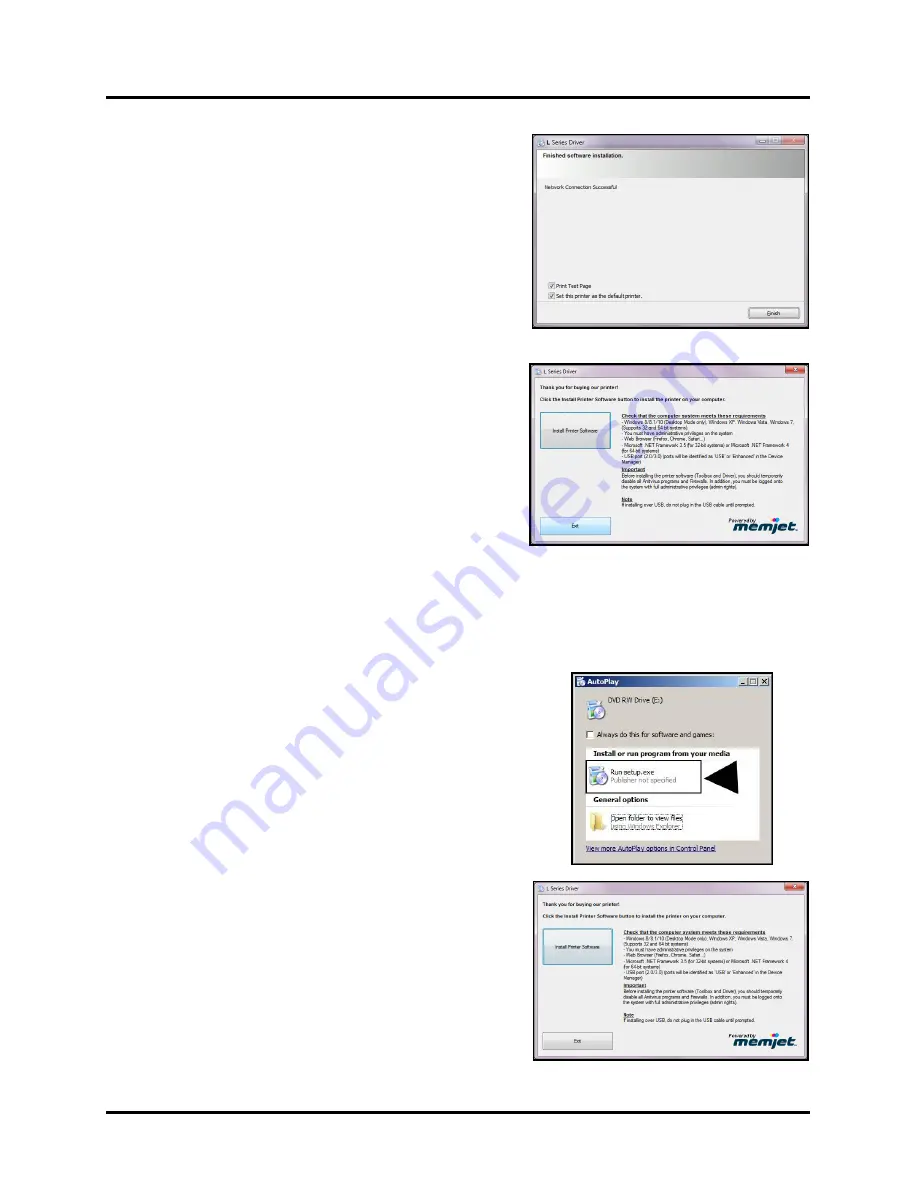

Finished software installation.

Do not check the

Test Page

as Printer is not set up yet. You can check “Set

this printer as the default printer” at this time.

Click

“Finish”

.

9.

Install Printer Software.

Click

“Exit”

to close CD.

10.

Restart computer to complete installation.

Install Over Network Connection, Version A

Use this procedure to install the Print Driver over the Network connection. This procedure works for almost all

networks that allow automatic assignment of the IP address (

factory default

).

NOTE: Copy the 12-digit Hardware ID number listed on the Printer(s) on the label located below the

Ethernet port so you can identify the Printer(s) in a later step.

1.

Check that Printer is plugged in and turned ON.

Make sure the

Ethernet (

network

) cable is plugged into the Ethernet port on

the Printer.

Install disk supplied with Printer in your CD drive.

When

AutoPlay

Window opens, click

“Run Setup.exe”

to start.

2.

Install Printer Software.

Make sure computer system

meets

minimum requirements

and you followed other

instructions listed on screen.

Click

“Install Printer Software”

.

Summary of Contents for AstroJet L1

Page 6: ......

Page 85: ......

Page 86: ...Copyright 2019 ASTRO MACHINE CORP Elk Grove Village IL 60007 03 12 2019 Part Number 200 L1...