page 36

speeds ranging from .06 to .19 sec. for 60° travel. Your choice

will be determined by your driving skills as well as your

budget because some of the high speed or high torque

servos can be very expensive. Below you will find a chart

which lists the servos that will bolt in or fit with only minor

modifications.

WARNING! We have determined that two of

the high torque Futaba servos will not work unless you modify

the servo mounting location in the truck. These are the S-

9302 and the S-9303 servos. If you choose to use these

servos, then making the servo fit will be your responsibility.

Guide to Recommended Servos

Airtronics

Futaba

JRpropo

94102

S148

5072

94322

S9403

5172

94737

S9304

47212

94738

S9402

47352

94151(Discontinued)

94152(Discontinued)

94155

94156

94157

Note: Futaba servos require that you file the servo

mounting tab holes so they are closer to the servo case to

allow the #7527 servo mounts to fit closer to the servo case.

See fig. 138. JRpropo servos may require that you trim the

servo mounting tabs' outer edge to clear the steering servo

saver and battery hold down strap. See fig. 139.

TRIM

SHADED

AREA

Futaba servos

Fig. 138

TRIM

SHADED

AREA

JRpropo servos

Fig. 139

The photos that follow show the installation of a

Airtronics 94737 high torque, high speed ball bearing me-

dium sized servo for the steering servo.

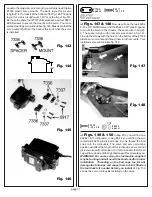

❏

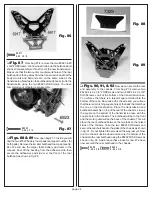

Figs. 140, 141 & 142

In bag #7-6 you will find

the #9180 servo horn tree (see fig. 140). On the parts tree are

servo horns that fit Airtronics, Futaba, & JRpropo servos.

Each servo horn is marked with the first letter of the brand of

radio the horn will fit.

Remove the correct servo horn from the parts tree.

Now go to bag #6-14 and remove one #6270 short ball end.

Thread the #6270 ball end into the #9180 servo horn from the

back side as shown in fig. 141. This will place the ball end over

the servo when mounted.

Note: KOpropo servos should be

able to use the Airtronics servo horn. If you are using a

different brand of servo and none of our servo horns will fit

you must then use one of the stock servo horns that came

with your servo.

Before you can install our servo horn you must

remove the stock servo horn that comes installed on most

servos. Now place the servo in front of you. With the output

shaft facing you make sure the shaft is on the right side of the

servo. Now install the servo horn so that it points straight up

as shown in fig. 142. Before you secure the servo horn, rotate

the servo horn to the right and left. We want to make sure the

servo horn has almost the same travel in both directions. If

not then you will need to remove the servo horn, rotate its

mounting position by one or more splines and recheck until

everything is correct. Your finshed servo should look like fig.

142.

Fig. 140

Fig. 141

Fig. 142

#627 0

4-40

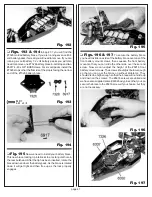

❏

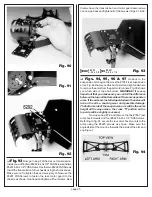

Figs. 143, 144, 145 & 146

In order to

properly install the steering servo, we will need to make any

servo modifications now. Refer back to figs. 138 & 139 for any

modifications to be made to Futaba or JRpropo servos.

In bag #7-6 you will find the #7336 plastic servo

mount parts (two mounts and two mount spacers) as shown

in fig. 143. From the same bag remove four #6917 4-40 x 3/

8" BHSScrews, and four #7337 servo shim washers (gold

colored).

The drawing in fig. 144 shows the maximum stan-

dard servo length. If your servo is longer you will need to add

the #7336 servo mount spacers. If your servo is smaller or