page 33

gap between the cap and the hex portion of the shock body

(see arrow in fig. 128). The O-ring will actually be doing the

sealing, so we must be careful not to overtighten the cap. As

soon as the cap comes in contact with the body just turn a little

bit further to seat it.

WARNING!!: not oiling the threads on

the plastic shock caps can cause them to seize onto the

shock body. You will not be able to remove the caps

when you go to service your shocks.

(5)Now work the shock shaft up and down about five

or six times, then push the shaft all the way in and let go of the

shaft. We want the shaft to come back out of the shock body

1/4" on its own. If it did not, pull the shaft all the way down then

unscrew the shock cap. Adjust the piston height inside the

shock body before you screw the cap on again according to

the following: If there was too much rebound (the shaft came

out too far on its own) then bring the piston closer to the top

of the shock body before you screw the cap on this time. If

there was not enough rebound then you will need to leave the

shock piston lower in the shock body before screwing the cap

on. If you have to make adjustments always recheck the oil

level before you make those adjustments. You are trying the

make sure all four shocks have the same rebound.

Fig. 126

Fig. 127

Fig. 128

❏

Figs. 129 & 130

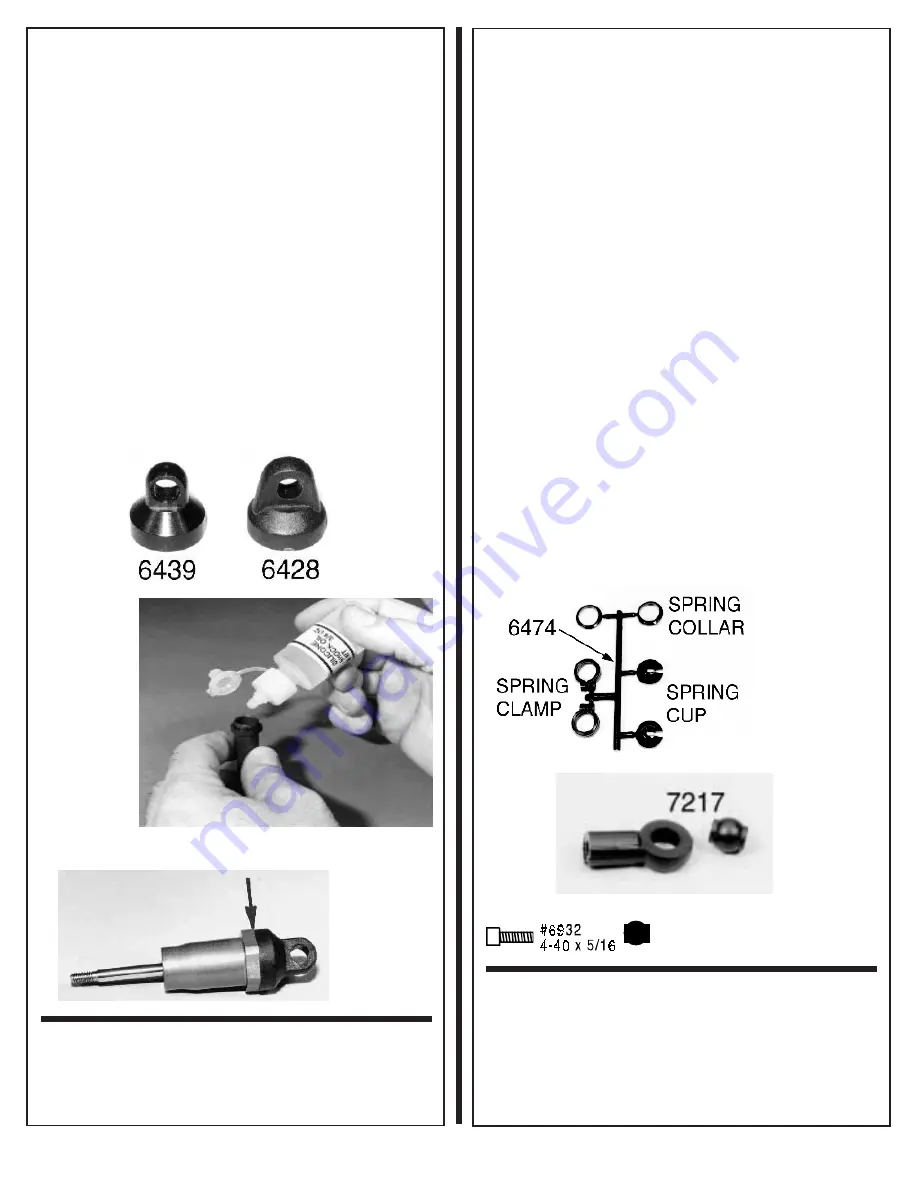

(1) From bag #7-11 remove the

two new #6474 spring clamps and cups parts trees and four

#6932 4-40 x 5/16" SHCScrews. Fig. 129 shows one of the

#6474 parts trees and identifies the three parts. (2) Now go

back to bags #7-9 and #7-10. Inside each bag there is a

smaller hardware bag. Remove two #7217 shock rod ends

and #7217 black plastic pivot ball ends (from each bag). (3)

Remove the shock spring clamp, spring collar, and spring

cup parts from the parts trees. (4) Slide the nylon spring

clamp onto each shock. To make it easier to adjust the

springs later, install the spring clamps so that the #6932

screws will be on the outside and facing forward on each

shock.(5) Each spring clamp has one open hole and one

closed hole for the tension screw. Install the #6932 screw

through each open hole and then thread it into the closed

hole. (6) Now slide the collar to the top of the shock body and

tighten it just enough to keep the collar from moving.

(7) Now take one of the #7217 shock rod ends and

push it into the plastic pivot ball. The easiest way to do this is

to place the ball end on a table or bench, set the nylon eyelet

over the ball and push down on the ball with your 1/4" nut

driver. You can also use needlenose pliers to squeeze the

parts together; just take your time and use the smooth part of

the jaws so you do not damage the plastic ball. Go ahead and

do the other three ball ends.

(8) Now thread the nylon shock rod end onto the

shock shaft. To keep the shock shaft from turning, you will

have to hold the shaft with your needle nose pliers.

WARN-

ING! Make sure you only grab the shaft with the smooth

part of the jaws of your needlenose pliers and as close

to the threaded end as possible. This is very important, for

we do not want to scratch the shaft where it will ride in the O-

rings, damaging the O-rings and causing the shock to leak.

Do the same for the other three shocks.

Fig. 129

Fig. 130

# 721 7

p iv ot ba ll

p la stic

❏

Fig. 131

Remove the two long #6480 (2.75" length)

rear green springs and two short #7427 (2.25" length) front

green springs from bag #7-11. Install one #6474 spring collar

onto each of the long rear green springs. Do the same for the

short front green springs. Slide the long springs onto the long

rear shocks. Next slide the short front springs onto the short

front shocks. Make sure the shock shaft is fully extended