page 37

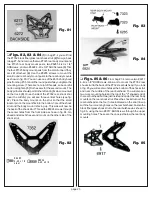

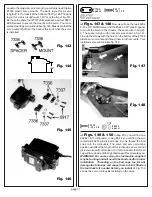

equal to the maximum servo length you will only need the two

#7336 plastic servo mounts. The parts layout for a servo

length of 1.40" or less is at the bottom of the fig. 145. The parts

layout for a servo length over 1.40" is at the top of fig. 145.

Both use the same four #7337 shim washers, and four #6917

BHSSscrews to secure the mounts to the servo. Your com-

pleted steering servo will look like fig. 146. Make sure that the

servo output shaft is to the back of the truck when the servo

is installed.

Fig. 143

1.40"

Fig. 144

Fig. 145

Fig. 146

#7336

spacer

# 69 17

4 -40 x 3 /8

❏

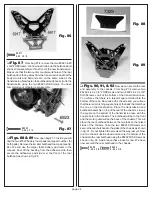

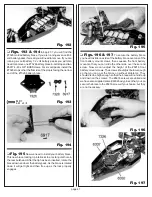

Figs. 147 & 148

Now we will use the two #6292

4-40 x 3/8" FHMScrews and the #6466 1/16" plastic spacer

to mount the servo to the chassis. These are also in bag #7-

6. The spacer will go on the rear screw as shown in fig. 147.

Line up the screws with the holes on the bottom of the #7336

plastic servo mounts and thread them into the mounts. Your

installed servo will look like fig. 148.

Fig. 147

Fig. 148

#62 92

4-40 x 3 /8

#6 46 6

sp ac e r

1/16

❏

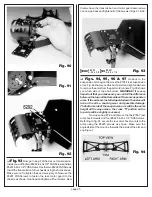

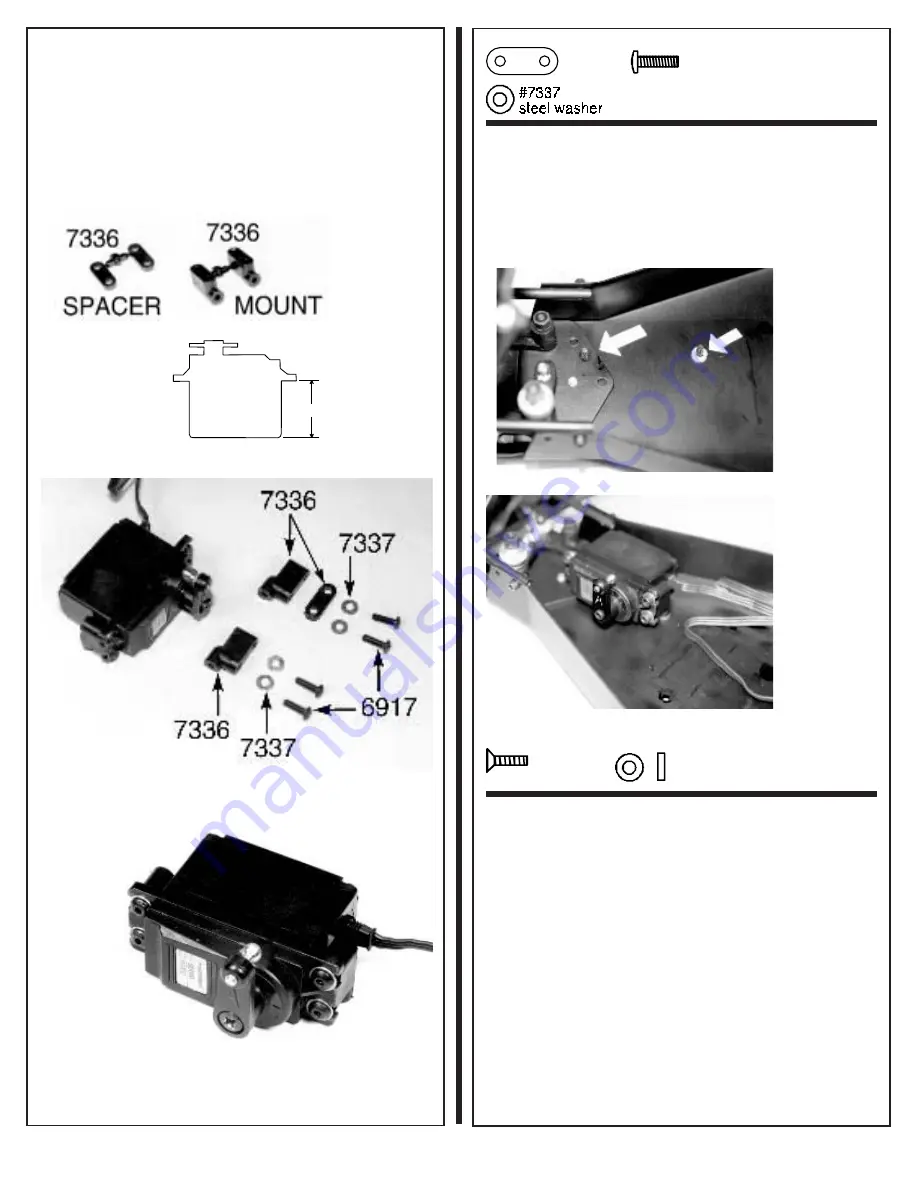

Figs. 149 & 150

In bag #7-2 you will find one

#6262 1.65" turnbuckle. In bag #6-14 you will find the two

remaining #6274 plastic ball cups. Evenly thread the ball

cups onto the turnbuckle. The servo and servo mounting

position will affect the length of this turnbuckle so we cannot

give you a specific dimension. On this turnbuckle the left ball

cup will face down and the right ball cup will face towards you.

WARNING! For some servos the turnbuckle supplied

may be too long and will need to be shortened for proper

installation. Threading on the ball cups too far will

damage the ball cups and cause them to bind. Shorten

the turnbuckle if needed before you install it. Fig. 150

shows the servo turnbuckle installed on the truck.