19

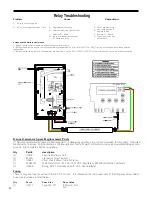

Trouble Shooting

Problem

Cause

Correction

After resolving the cause of any error code or any service valve, press NEXT & REGEN simultaneously for 5 seconds or disconnect power supply for

5 seconds at PC board and reconnect to resynchronize software with piston position.

valve eRROR COdes

Error Code 101

‑

Unable to recognize

A1. Control not reading piston position

A1. Resynchronize software with piston position by

start of regeneration

pressing start of regeneration NEXT and REGEN

buttons simultaneously for 5 seconds, until screen

changes. Initiate regeneration to verify function by

pressing and holding REGEN button until regeneration

initiates, step through regeneration modes by pushing

REGEN button each time motor stops.

A2.

Verify motor connection to PC board; motor wires

intact

and motor fully inserted to engage pinion.

A3. Verify correct assembly; PC board snapped onto

drive

bracket and wires are in backplate guides and drive

bracket snapped onto backplate. Verify three drive

gears are in place on drive bracket.

Error Code 102

‑

Unexpected stall

B1. Mechanical Binding

B1a

. Check for any foreign material in stack assembly

impeding piston movement and remove; verify seals

intact and

in place, if not, replace stack assembly and piston. B1b

. Check

for incorrect assembly, drive bracket not snapped

into place, motor pushed inside of barrel of drive bracket

(black gear on motor end should be flush with end of shaft).

B1c. Drive gears unable to rotate freely

‑

replace gear(s) if not

rotating freely.

B2. Buildup on piston

B2.

Clean with soft cloth and vinegar, or replace piston

B3. Improper voltage being delivered

B3. Motor unable to move piston, check voltage is present

to board

on 12V DC motor at start of regeneration modes.

Transformer should provide 12 volts when plugged

into outlet and not attached to board - if not replace

transformer

Error Code 103

‑

Motor ran too long,

C1. High drive forces on piston

C1. Loosen drive cap gear 1/4 turn

timed out trying to reach next position

C2. Address high drive forces

C3. Motor failure during regeneration

‑

replace motor

Error Code 104

‑

Motor ran too long,

D1. Piston unable to reach home position

D1. Incorrect assembly; check drive bracket is

correctly timed out trying to reach home position

seated and snapped into place on backplate,

wires

outside of guides on backplate can impede drive

bracket from correct position.

D2. Check PC board is seated on posts and snapped

into place on drive bracket

D3. Drive gear labels dirty or missing, missing or broken

gear, replace as needed

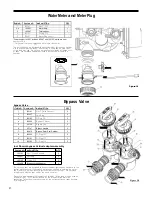

Mav eRROR COdes

After resolving any MAV error or servicing MAV, resynchronize software with piston positioning by pressing NEXT and REGEN buttons simultaneously for 5

seconds

or disconnecting power from PC board for 5 seconds and reconnecting.

AlTERNATING MAV DRIVE - ERROR CODES 106 & 107

Error Code 106

‑

Alternating MAV ran too long

A1. Control valve is programmed for alternating or as

NHWB without having MAV connected to board.

Reprogram valve to proper setting or connect MAV

to alternating MAV drive on PC board

A2. MAV motor not fully engaged with

gears

Error Code 107

‑

Alternating MAV stalled B. Mechanical Binding

B1. Open MAV and check for foreign material on stack

assembly, remove if present, verify seals intact and in

place. If not, replace stack assembly

B2. Drive gear should spin freely

‑

replace if necessary

aUXIlIarY MaV drIVe - errOr cOdeS 116 & 117

error code 116

‑

Auxiliary MAV ran to long

A1. Control valve is programmed for auxiliary MAV without

having MAV connected to board. Reprogram valve to

proper setting or connect MAV to two

‑

pin connection

labeled auxiliary drive on PC board

A2. MAV motor not fully engaged with

gears

error code 117

‑

Auxiliary MAV stalled

B1. Open MAV and check for foreign material on stack

assembly, remove if present, verify seals intact and in

Summary of Contents for PurAzone A03

Page 1: ...PurAzone A03 Filtration PurAzone A03 Filtration Filter Manual Owner s Filter Manual 2013 2014...

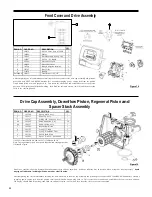

Page 5: ...5 Figure 2 Figure 4...

Page 14: ...13 NEXT to go to Step 15S...

Page 18: ...17 RETURN TO NORMAL MODE...

Page 20: ...16 NEXT to go to Step 10CS...

Page 34: ...28...