15

Cycle Options

BACKWASH

REGENERANT

DRAW

FILL

RINSE

FILTERING

END

Cycle Sequence

Anytime cycle sequence is modified, filter set-up will revert to manu

-

facturer setting and must be reprogrammed as desired.

Cycle Sequence instructions allows the operator to set the order of the

cycles. The Filter System Setup allows the operator to set how long the

cycles will last. The operator may choose up to 9 cycles in any order.

END must be used as the last cycle option. The FILTERING cycle should

only be used in regenerant prefill applications.

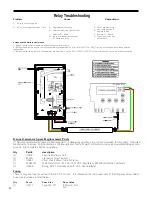

The following is an example of how to set a valve so that when regeneration is initiated, BACKWASH occurs first,

REGENERANT DRAW DN occurs second, RINSE occurs third, and FILL occurs fourth.

STeP 1cS

STeP 1cS

–

Press NEXT and

simultaneously until TYPE appears on screen and release.

Then press NEXT and

simultaneously again for 3 seconds and release. If screen in step

2CS

does not appear in 5 seconds the lock on the valve is activated.

ValVe TYPe

SeT

1.0

In

STeP 2cS

STeP 2cS

–

Valve Type.

Use the

or

to select from 1.0", 1.25", 1.50", 2.0L", 2.0"

valve. ProMate

‑

6.0 Iron Blaster™ is a 1.0” meter. Press NEXT to go to Step 3CS.

alTernaTOr SYSTeM

STeP 3cS

STeP 3cS

– Use the

or

to select one of the following:

•

Twin alternating System

– Select Alt A or Alt B, See instructions in Step 4CS; or

SeT

OFF

•

System board

‑

Allows Demand Recall Programming – See instructions in Step 9CS.

•

no Hard Water bypass during regeneration

– See instructions in Step 6CS.

•

reclaim enabled

‑

Allows control to operate in Reclamation Mode – See instructions in Step

8CS.

•

Separate Source enabled

‑

Allows control to have a separate water source during the

regeneration cycle. See instructions in Step 7CS.

•

OFF; Factory Setting is OFF -

Press NEXT to go to Step 10CS.

alTernaTOr SYSTeM

STeP 4cS

STeP 4cS

–Twin alternating System –

Allows automatic alternation between two units to provide

SeT

alT a

filtered water 24 hours a day.

Use

or

buttons to select ALT A or ALT B

Select ALT A for the control valve that has the two

‑

pin connector labeled MAV DRIVE connected

to

the alternator valve.

Select ALT B for the control valve that wil be connected via three

‑

prong connector labeled

INTERCONNECT. Must use 3

‑

wire interconnect cable. Press NEXT to go to Step 5CS.

For Alternating System, change programming:

• Set softener, with volume capacity in GALLONS and select

Regeneration Time Option “IMMEDIATE” or "DELAYED" and select DAYS BETWEEN

REGEN

as desired.

• For complete programming, see Twin Alternating MAV manual.

delaYed rInSe & FIll

STEP 5CS

STEP 5CS –

Select Twin alternating Option.

SeT

OFF

MIn

Use

or

buttons to select

• Standard

‑

Standard Alternating Function

• Refresh Rinse

‑

Alternates every 6am & 6pm and runs programmable number of

gallons to service. Press NEXT to set number of gallons.

• Delayed Rinse and Fill

‑

See below

• Factory Setting is Standard Alternating Function

This option delays the last two cycles of regeneration (only "Rinse" and "Fill").

This feature splits the regeneration into two portions. The first portion of the

regenera

-

tion will start immediately and all programmed cycles before the "Rinse"

and "Fill" cycles will be performed. After all programmed cycles before "Rinse"

and "Fill" are completed the control valve will drive to the service position

(displaying "Delayed Rinse + Fill Pending"). When the volume of the on

‑

line unit

is depleted to 10% of its programmed capacity, the control valve will be triggered

to finish the second portion of the regeneration and complete the "Rinse" and "Fill"

cycles and return to Service

and be placed into Standby mode, and wait to come on

‑

line for service. Press

Summary of Contents for PurAzone A03

Page 1: ...PurAzone A03 Filtration PurAzone A03 Filtration Filter Manual Owner s Filter Manual 2013 2014...

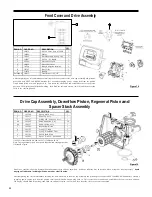

Page 5: ...5 Figure 2 Figure 4...

Page 14: ...13 NEXT to go to Step 15S...

Page 18: ...17 RETURN TO NORMAL MODE...

Page 20: ...16 NEXT to go to Step 10CS...

Page 34: ...28...