21

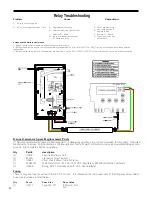

Trouble Shooting

PROBLEM

CAUSE

CORRECTION

1. Control valve stalled in regeneration

A.

B.

C.

D.

E.

F.

G.

Motor not operating

No electric power at outlet

Defective transformer

Defective PC board

Broken drive gear or drive cap assembly

Broken piston retainer

Broken main or regenerant piston

A.

B.

C.

D.

E.

F.

G.

Replace Motor

Repair outlet or use working outlet

Should provide 12 volts when plugged into outlet,

if not, replace transformer

Replace PC board

Replace drive gear or drive cap assembly

Replace drive cap assembly

Replace main or regenerant piston

2. Blank or incomplete LED display

A.

B.

C.

D.

E.

F.

Transformer unplugged

No electric power at outlet

Defective transformer

Short in meter

Check battery, should be greater than 3 volts

Defective PC board

A.

B.

C.

D.

E.

F.

Connect to power

Repair outlet or use working outlet

Should provide 12 volts when plugged into outlet,

if not, replace transformer

Unplug meter from PC board, if LED lights appropriately,

replace meter assembly.

Replace battery if less than 3 volts

Replace PC board

3. Control does not display correct

A.

B.

Power outage > 2 years

time of day

Power outage < 2 years, time of day flashing,

battery depleted

A.

B.

Reset time of day, replace lithium coin type battery

on circuit board

Reset time of day, replace lithium coin type battery

on circuit board

4. No “filtering” display when

water is flowing

A.

B.

C.

D.

E.

Bypass valve in bypass position

Meter connection disconnected

Restricted/stalled meter turbine

Defective meter

Defective PC board

A.

B.

C.

D.

E.

Put bypass valve in service position

Connect meter to PC board

Remove meter and check for rotation, clean

foreign material

Replace meter

Replace PC board

5. Control valve regenerates at

wrong time of day

A.

B.

C.

D.

E.

Power outages

Time of day not set correctly

Time of regeneration incorrect

Control valve set at “on 0”

(immediate regeneration)

Control valve set at on 0

A.

B.

C.

D.

E.

Reset control valve to correct time of day

Reset to correct time of day

Reset regeneration time

Check control valve set-up procedure

regeneration time option

Check control valve set-up procedure

regeneration time option

Ozone Generator Troubleshooting Guide

SYMPTOM

POSSIBLE CAUSE

CORRECTION

1. Ozone unit does not turn on

A.

B.

C.

Unit not wired correctly to relay

Unit not programmed correctly

Blown fuse

A.

B.

C.

See wiring diagram on page 20

See program on page 11. Relay should be

programmed

on Time. Set time to start last minute of rinse cycle.

Duration should be programmed for length of time to

draw ozone into top of filter bed.

Replace fuse with equally rated substitute

2. Unit keeps blowing fuses

A. Electrical short in unit

A. Visually inspect unit, and check for loose

connections. Inspect printed circuit board for burn

marks. Inspect

HV wire from printed circuit board to ozone cell for

disconnection or burn marks. Repair any and all

problems prior to placing unit in service, or contact

factory for service information

B.

C.

Incorrect fuse value and type

are being used

Unit is connected to improper power

source

B.

C.

Replace with appropriate size/type fuese. Refer to

Spare/Replacement parts for replacement part

information

Refer to lavel on side of chassis for correct voltage

requirements

3. Unit turns on, but no ozone output

A.

B.

C.

D.

Frequency driver is defective

Frequency driver is high voltage lead(s)

not connected to ozone cell(s)

Water has been allowed to back up into cell

Cell is plugged with a build

‑

up of nitrous

byproducts and particulate matter. Usually

caused by the lack of proper air preparation

A.

B.

C.

D.

Replace frequency driver

Connect lead(s) to Corona Discharge Cell(s)

Replace cell(s)

Replace cell(s)

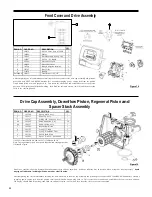

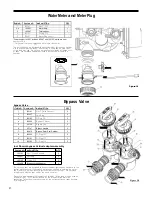

Summary of Contents for PurAzone A03

Page 1: ...PurAzone A03 Filtration PurAzone A03 Filtration Filter Manual Owner s Filter Manual 2013 2014...

Page 5: ...5 Figure 2 Figure 4...

Page 14: ...13 NEXT to go to Step 15S...

Page 18: ...17 RETURN TO NORMAL MODE...

Page 20: ...16 NEXT to go to Step 10CS...

Page 34: ...28...