9

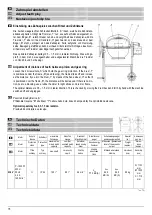

Mixing

Mixer setting:

To make concrete or mortar, the mixing drum must be locked in a

specific position. Only the proper mixer setting ensures optimal

mixing results and smooth operation.

Hold rotating lever or handwheel tightly while rotating.

Loosen the rotating mechanism.

Rotate the mixing drum up to the appropriate recess for the

material you are mixing.

allow rotating mechanism to lock into place.

Additional safety instructions

•

Only fill or empty the mixing drum when the motor is running.

•

Check the stability of the mixer.

Preparing material for mixing:

1. Pour in water and few shovels full of aggregate (sand, gravel,

...).

2. Add a few shovels full of binding agent (cement, lye, ...).

3. Repeat steps 1 and 2 until you reach the proportions required

for mixing.

4. Allow material to mix thoroughly.

Have a professional advise you regarding the composition

and quality of the material being mixed.

Emptying the mixing drum:

Hold the rotating lever or handwheel tightly

1. Unlock rotating mechanism or step on brake

2. Slowly tilt mixing drum

Transport

Pull plug each time before transport.

Point the opening of the mixing drum downwards during

transport or storage.

Storage

In order to increase the service life of the concrete mixer

and operate it without glitches, the rotating mechanism

should be treated with an environmentally compatible spray

oil before the mixer is put into storage for unusually long

periods.

Cleaning

Additional safety instructions

Pull plug each time before cleaning.

•

Switch off machine and pull plug if you have to touch the

machine (with hand, brush, scraper, rag, etc.) while cleaning

it.

•

Protective devices removed for cleaning must be properly

remounted before starting the machine.

•

Do not spray water directly on the motor or the switch, nor on

the ventilation apertures in the motor housing.

Notes on cleaning:

•

Before taking a break and after finishing work, clean the

concrete mixer inside and out.

•

Do not pound on the mixing drum with hard objects

(hammer, shovel, etc.). A dented mixing drum impairs mixing

operations and is difficult to clean, besides.

•

To clean the inside of the drum, put in some water and a few

shovels full of gravel and set the drum to revolving.

•

Remove any concrete or mortar left sticking to the teeth of

the axle-drive bevel gear or the crown gear segments

immediately.

Maintenance

The concrete mixer requires practically no maintenance.

The mixing drum and drive shaft are bedded on ball bearings with

permanent lubrication.

Never grease the ring gear!

To preserve the value of the mixer and increase its service life,

handle it as described in "Transport and storage". Furthermore,

the concrete mixer should be checked regularly for signs of wear

and tear or functional deficiencies. This applies especially to

moving parts, screw connections, protective devices and

electrical parts.

B

Concrete

M

Mortar

E

Emptying