8

•

Do not reach into mixer when it is

running ( rotating mixing apparatus).

Observe enough safety distance to the

concrete mixer. Prevent any contact to rotating or moving

parts of the machine.

•

Fill or empty the mixing drum only when the motor is running.

•

Observe the mixer's direction of rotation.

•

Do not alter the revolution speed of the motor, since this

controls the safe maximum operating speed, and protects the

motor and all rotating parts against damage due to excess

speed.

•

Concrete mixers which the manufacturer has not intended for

towed vehicle operation may only be run by means of a hand

wire pull.

•

Be absolutely sure to pull the plug before:

−

moving or transport

−

cleaning, maintenance or repair work

−

eliminating faults

−

checking connecting lines, whether these are knotted or

damaged

−

leaving unattended (even during short interruptions)

•

Check the machine for possible damage:

−

Before further use of the machine the safety devices must

be checked carefully for their proper and intended

function.

−

Check whether movable parts function perfectly and do

not stick or whether parts are damaged. All parts must be

correctly installed and fulfil all conditions to ensure perfect

operation of the machine.

−

Damaged safety devices and parts must be properly

repaired or exchanged by a recognized, specialist

workshop; insofar as nothing else is stated in the

instructions for use.

−

Damaged or illegible safety labels have to be replaced.

•

Store unused equipment in a dry, locked place out of the

reach of children.

Shockproof concrete mixers

(Protection Class II)

•

Only start the machine when the panelling is complete and

fully closed.

•

Protection Class II applies only if original insulating material

is used for repairs and insulation clearances are not altered.

Electrical safety

Danger to life and limb if not observed!

•

Connecting attachments must be designed in conformance

with IEC 60245-4:1980 (DIN 57 282) and marked H 07 RN-F,

or comparable models. Cross section of wires at least 3 x 1.5

mm² up to a maximum length of 25 m. Wire cross-section at

least 2.5 mm² for lengths of more than 25 m.

•

Use only connecting attachments with a rubber plug device

for severe requirements

that is protected against

spraying water.

•

Long and thin connection lines result in a potential drop.

The motor does not reach any longer its maximal power;

the function of the device is reduced.

•

Unwind the cable completely when using a cable drum.

•

Do not use the power cords for purposes they are not

intended for. Protect the cable against heat, oil and sharp

edges. Do jerk on the power cable when pulling the plug from

the socket.

•

Check connecting attachments for defects or ageing before

using them.

•

Never use defective connecting attachments.

•

When laying the connecting attachments, be sure that they

do get crushed or bent, and that the plug-and-socket

connection does not get wet.

•

Do not use any provisional electrical connections.

•

Never bridge over protective devices or put them out of

operation.

•

Only hook up the machine by means of a

fault-current circuit breacker: 30 mA!

A licensed professional electrician must make all electrical

connections and repairs, and observe local regulations in

doing so, especially those regarding protective measures.

The manufacturer or a company designated by the

manufacturer must attend to the repair of all electrical

parts on the machine.

Use only original spare. Accidents can arise for the user

through the use of other spare parts. The manufacturer is

not liable for any damage or injury resulting from such

action.

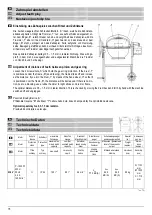

Start-up

Observe all safety instructions.

Setting up the machine:

•

Set up and run the concrete mixer on a

solid, level base only (where it will not tip over).

•

Keep the machine from sinking into the ground or floor.

Adhere to accident prevention regulations (danger of

tipping).

•

When setting up the machine, make sure that the mixing

drum can be emptied without obstruction.

Switching on and off

Be sure that

−

all protective devices are on the mixer and properly mounted.

−

all safety instructions are adhered to.

•

The on/off switch is located beneath the motor housing.

Switch the motor on and off only at the switch.

•

In the event of a power failure, the machine will switch off

automatically. Press the switch again to restart the machine.

Motor protection

The motor is equipped with a thermostat. The thermostat

switches the motor off automatically in the event of overload

(overheating). The machine can be restarted after a cooling-off

period.