6

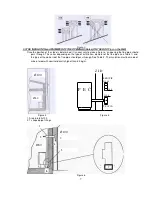

Figure 1

Figure 2

− Smoke is discharged directly into the flue pipe (chimney) only if its cross section is up to 15 x 15 cm or if its

diameter is up to 15 cm and if it has a cover for the purposes of inspection and cleaning.

−

If the cross section of the chimney is larger

than 15x15cm or its diameter is larger than 15cm, the possible

control of increased draught (decreasing) in the chimney can be performed in three ways:

1. If there is an opening for the purpose of cleaning at the bottom of the chimney, it should be partially opened.

2. A steel pipe with a diameter of 10 cm should be inserted into the chimney if you have elements for such a

refurbishment of the chimney.

3. By the regulation of certain parameters in the stove. This regulation can be performed only by an authorized

service centre of Alfa plam.

− Ensure that the connection for the house chimney is properly sealed.

− Avoid any contact with easily combustible material (such as wooden beams), and in any case these should be

insulated with fire resistant material (see Figure 2).

A) Mineral wool

B) Steel pipes

C) Partition plate.

The stove is designed for the connection to the chimney with flue pipes whose diameter is 80mm. If the standard

chimney is not used but a new one is being constructed or the existing chimney is being refurbished, use insulated

stainless steel pipes (double wall) with a diameter in accordance with Table 1. The use of flexible pipes is not

allowed.

SYSTEM TYPE

DIAMETER mm

SYSTEM ASSESMENT

Pipe shorter than 5 m

80

acceptable

Pipe longer than 5 m

100

obligatory

Installation at places where the elevation above the sea

level is higher than 1,200 meters

100

recommendable

Table 1

When you use a connecting pipe between the stove and the discharge flue pipe, you must also use a “T” coupling

(as it is shown in Figures 5 and 6), with the cover for the purpose of cleaning (plug) next to the stove. The

application of this “T” coupling must enable the collection of ashes generated inside the pipe and cleaning of the

discharge flue pipe from time to time without removing the pipe. The smoke is under mild pressure. Because of this,

it is necessary to check if the opening i.e. the cover (plug) for cleaning the smoke discharge system is perfectly

sealed and if it remains perfectly sealed after each cleaning. Ensure that the assembly is carried out in the same

order and check the condition of the seal.

The installation of the flue pipes should be performed in accordance with Figure 7.

It is strictly recommended to avoid using horizontal extensions or elongations and if this is necessary, ensure that

the pipe is not counter leaned but that it has an inclination of at least 5%. The horizontal extensions must never be

longer than 3 m.

It is not recommendable to connect the flue pipe directly to the stove with a horizontal extension longer than 1 m.

See Figures 4, 5, 6 and 8. It is necessary to put a vertical extension of Ø 80mm with a length of at least 1-1.5 m

after the “T” claw, and only after that proceed to a horizontal extension of Ø 80mm and a vertical extension of Ø 80

or Ø 100mm depending on the height of the flue pipe (chimney), as it is shown in Table 1.

Figure 3 on the left shows how the end (top) of the chimney should look like when there are two chimneys one next

to the other, and Figure 3 shows how the end should not be executed.