4

− The type of the stove that is being installed,

− Whether the room in which the stove is being installed is appropriate, which is expressed as the minimum size of

the room required for the installation as prescribed by the stove manufacturer,

− Instructions of the heat generator manufacturer, related to the requirements of the smoke discharge system

(smoke discharge ducts and pipes),

− The internal cross section of the chimney, material the chimney is made of, cross-sectional uniformity, whether

there are any obstacles and barriers in the chimney,

− The height and vertical extension of the chimney,

− The height above the sea level at the place of installation/incorporation,

− The existence and suitability of a wind resistant protective cover of the chimney,

− The possibility of providing the external air intake and the size of required openings,

− The possibility of the simultaneous use of the stove which is to be installed, together with the other equipment

already existing in that place.

If the results of all the checkups are positive, then the installer may proceed with the incorporation/installation of the

stove. The instructions provided by the stove manufacturer, as well as the fire prevention standards and safety

standards must also be observed.

When the installation is completed, the system must be put into a trial operation for at least 30 minutes in order to

check up all the packing and seals of the system.

When the incorporation and significant details are completed, the installer is obliged to provide the client with the

following:

− The Use and Maintenance Manual issued by the stove manufacturer (if such a manual has not been delivered

with the stove),

− The documents required for the compliance with existing standards.

3.0 THE INSTALLATION – INCORPORATION OF THE STOVE

The user shall be fully responsible for the works executed at the incorporation site.

Before putting the stove into operation, the installer must meet all legal safety standards, in particular:

− Ensure that the stove installation is in accordance with local, national and European regulations,

− That it fulfils the requirements stated in this document,

− That the installation of the flue piping and air intake corresponds to the type of the installed stove,

− That the electric connections must not be executed with the use of temporary and/or non-insulated electric cables,

− Check the efficiency of the electrical system grounding,

− Always use the personal protective equipment and all the protective means prescribed by applicable local

regulations,

−

Always ensure sufficient servicing space required for any maintenance and repairs of the stove.

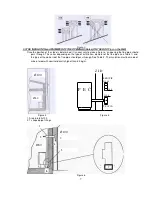

3.1 PLACING THE STOVE

We advise you to unpack the stove only when it is put in the place where it is to be installed.

The stove stands on plastic legs with cast-in screws M10 (4 pieces) screwed into the base of the stove. Nuts

M10mm are screwed onto the screws up to the plastic part. The legs are also maximally screwed, up to the base of

the stove. When you unpack the stove and bring it to the spot on which it is to be installed, unscrew all the legs to

obtain the total height from the floor to the stove base i.e. to ensure that the legs are protruded from the stove base

for around 25mm. When you finish levelling the stove which should stand horizontally, tighten the nuts while holding

the plastic part of the leg with your hand. Tighten the nuts using spanner 17 so that they reach the stove base. The

height of around 25mm from the floor to the stove base is needed for air circulation and better stove cooling. In this

way, you will protect the stove against overheating and extend its service life.

If the surrounding walls and/or floor are made of materials that are

not heat resistant

, appropriate protection

should be used consisting of incombustible insulation material.

Always ensure a safe distance (around 35/40 cm) between the stove and your furniture, home appliances, etc. In

order to protect the floor, if it is made of combustible material, we suggest that you put on the floor, under the stove,

a metal plate with a thickness of 3 to 4 mm that would protrude for 30 cm ahead of the stove front.

The stove must be placed at a distance of at least 25 cm from the surrounding walls.

Always leave at least 15

cm between the back of the stove and the wall in order to ensure the proper circulation of air, i.e. to allow air to

properly flow through this space.

If the stove is to be placed in a kitchen with a ventilation grid, or if it is to be placed in rooms with solid fuel heat

generators (such as wood burning stoves), always ensure that the quantity of the inlet air (into the kitchen or room)

is sufficient to provide the safe operation of the stove.

If the smoke discharge channel should pass through the ceiling, the ceiling should have proper thermal insulation

made of incombustible insulating material. Once the stove is placed, it should be levelled with the use of the

adjustable legs.

DANGER

The smoke discharge fittings

MUST NOT

be connected to: