18

Valve safety cap should be loose, not too tight, so that the air could freely leave the boiler and remain of

installation.

11.4. EXPANSION TANK

Furnace has built-in expansion tank with 10l volume. Function of the tank is pressure stabilisation in the boiler and

in the heating system installation. Factory setting of the pressure in the tank is 1 bar.

11.5. FILL AND DRAIN COCK

Purpose of the cock is filling and draining of the installation.

It is positioned on the rear bottom side.

Inlet connector is R1/2", and outlet connector has hose extension.

12. FILLING THE INSTALLATION AND PUTTING INTO OPERATION

Before heating season, entire heating system should be filled with water, ventilated, and the stove should be

properly connected to the chimney, following above mentioned explanations.

Working water pressure is recommended to be 1 – 2 bars. Ideally between 1.2 and 1.6 bar.

Test pressure can reach 2.4 bars.

NOTE:

Furnace must not be used without water. It must be connected to the installation system with radiators with

minimum power of 8 KW.

13. PRACTICAL GUIDELINES FOR USING HEATING SYSTEM

-All connectors must be properly sealed and tightened. There must not be any water leakage.

-Complete installation should be checked with water under the test pressure of 2.4 bars before putting into

operation.

-System should be drained at least once because of the dirt inside it.

-Make sure that all valves between furnace and installation are open.

-Make sure to release air from the boiler and heating system prior to putting into operation.

-During ignition and cooling fazes, furnace might change in volume in response to a change in

temperature and that might cause crackling noises. That is absolutely normal, since the construction is

made out of steel and it could not be considered as deficiency. A basic fabric setting guarantees proper

functioning and prevents overheating.

14. FILLING WITH WOOD PELLET

Furnace is filled with fuel from the upper side by opening the lid. Put the wood pellets into the furnace; its capacity is

approximately three 15 kg bags.

To simplify this procedure, split it to two segments:

-Put the half of the bag into the furnace and wait until pellets reach the bottom. Ignite the furnace.

-After the furnace starts to work normally, add the pellet as needed.

-Never remove the safety grill from the reservoir. During pellet filling, make sure that the pellet bag does not get in

touch with hot surfaces.

15. DESCRIPTION AND FUNCTIONING OF THE FURNACE OPERATION CONTROLLER

15.1. USER INTERFACE

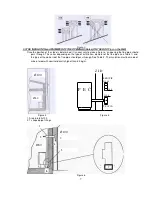

The display unit enables communication with the controller by simple pressing on certain buttons.

15.1.1. Push-button display

Display shows information about furnace operation status. Accessing the menu, user can get various kinds of

information review and can make available adjustments according to level of access.

Figure 20

shows an example of a display representation.

Figure 20