D

ISASSEMBLY

9

2480 Remote Intensifier Tooling Alcoa Fastening Systems

NOTE: The following procedure is for complete

disassembly of tool. Disassemble only components

necessary to replace damaged O-rings, Quad rings,

Back-up rings, and worn or damaged components.

Always use soft jaw vice to avoid damage to tool.

DISASSEMBLY OF HEAD

For list of Item Numbers and their locations, refer to

complete Tool Assembly Drawing and Parts List.

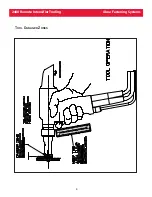

I.

See

WARNING

above. Disconnect tool’s electrical

connector from hydraulic unit. Uncouple tool’s

hydraulic hoses.

2.

Remove nose assembly from tool.

3.

Remove four Socket Head Cap Screws (99) and

Locknuts (100) from handle assembly. Separate

Handle (19) halves.

(Figure 1)

4.

Lift Air Trigger Assembly (1) from Handle half. Pull Air

Hose out of handle’s built-in strain relief.

(Figure 1)

5.

Unscrew Hydraulic Hoses (63) from tool.

(Figure 9)

Drain hoses into container. Piston (4) can be pushed

to rear of Cylinder (12) to drain fluid. Discard fluid.

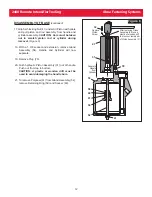

6. Disassemble cylinder and piston assembly as follows:

a.) Place Spacer over threaded end of Piston

(Figure

2a)

. Thread Piston Assembly Tool onto Piston. If

Cylinder contains fluid, push Piston to rear and

drain into container. Discard fluid.

b.) Remove Pintail Deflector (18) from tool by twisting

and pulling in one motion. With a 1 5/16 open end

wrench, unscrew End Cap (17).

c.) Thread Piston Insertion Tool into back of Cylinder.

(Figure 2b)

d.) Supporting tool as shown, press (or drive) Piston,

Rear Gland (13) assembly and Front Gland (10)

assembly out of Cylinder.

(Figure 2c)

continued

WARNING: Be sure to disconnect Tool’s

control trigger system from POWERIG®

Hydraulic Unit before disconnecting Tool’s

hydraulic hoses from unit. If not disconnected

in this order before any maintenance or

cleaning is done, severe personal injury may

occur.

!

Left half of

Handle (19)

Right half of

Handle (19)

Locknut

(100)

Qty. 4

Hydraulic Hoses

(63)

Qty. 2

Head Assembly

Air Trigger

and Hose

Assembly (1)

Socket Head

Cap Screw (99)

Qty. 4

Figure 1