8

2480 Remote Intensifier Tooling Alcoa Fastening Systems

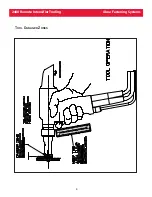

The Model 2480RI Installation Tool is shipped with a plastic

plug in the air swivel connector. The swivel has 1/4-18

female pipe threads to accept the air hose fitting. Quick

disconnect fittings and 1/4” inside diameter air hose are -

recommended. An air supply of 90-100 psi capable of 11.5

CFM must be available. Air supply should be equipped with

a filter-regulator-lubricator unit.

1. Remove plastic shipping plug from Air Inlet Connector

and screw quick disconnect fitting into Air Inlet

Connector.

2. Set air pressure on regulator to 90-100 psi.

3. Connect air hose to tool.

4. Cycle tool a few times by depressing and releasing

trigger.

5. Select proper Nose Assembly for fastener to be

installed.

6. Attach nose assembly to tool .

7. Install fastener(s) in test plate of proper thickness with

proper size holes and inspect fastener(s).

NOTES:

1 Air quick disconnect fittings and air hoses are not

available from Huck International, Inc.

G

ENERAL

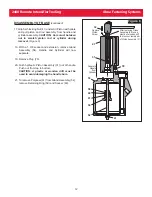

1. The efficiency and life of any tool depends upon proper

maintenance. Regular inspection and correction of

minor problems will keep tool operating efficiently and

prevent downtime. The tool should be serviced by

personnel who are thoroughly familiar with how it

operates.

2. A clean, well-lit area should be available for servicing

the tool. Special care must be taken to prevent

contamination of pneumatic and hydraulic systems.

3. Proper hand tools, both standard and special, must be

available.

4. All parts must be handled carefully and examined for

damage or wear. Always replace Seals, when tool is

disassembled for any reason. Components should be

disassembled and assembled in a straight line without

bending, cocking, or undue force. Disassembly and

assembly procedures outlined in this manual should

be followed.

5.

Service Parts Kit 2480RIKIT

includes consumable parts

and should be available at all times. Other components,

as experience dictates, should also be available.

D

AILY

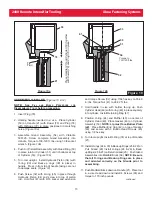

1. If a Filter-Regulator-Lubricator unit is not being used,

uncouple air disconnects and put a few drops of

Automatic Transmission Fluid or light oil into the air

inlet of the tool. If the tool is in continuous use, put a

few drops of oil in every two to three hours.

2. Bleed the air line to clear it of accumulated dirt or water

before connecting air hose to the tool.

3. Check all hoses and couplings for damage or air leaks,

tighten or replace if necessary.

4. Check the tool for damage or air/hydraulic leaks,

tighten or replace if necessary.

5. Check the nose assembly for tightness or damage,

tighten or replace if necessary.

6. Check oil level in tool reservoir, replenish if necessary.

W

EEKLY

1. Disassemble and clean nose assemblies and

reassemble per applicable NOSE ASSEMBLY DATA

SHEET.

2. Check the tool and all connecting parts for damage or

oil/air leaks, tighten or replace if necessary.

!

WARNING: Inspect tool for damage or wear

before each use. Do not operate if damaged or

worn, as severe personal injury may occur.

P

P

REP

REP

ARA

ARA

TION

TION

FOR

FOR

U

U

SE

SE

S

S

ER

ER

VICING

VICING

THE

THE

T

T

OOL

OOL