Fill Point

Fill Bottle

(94)

Plastic

Tube (93)

Connector

(92)

17

2480 Remote Intensifier Tooling Alcoa Fastening Systems

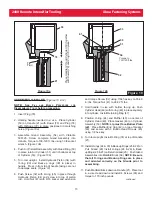

FILL AND BLEED PROCEDURE FOR

ASSEMBLED TOOLS THAT NEED RE-

BLEEDING

(Figure 12)

If the tool is not developing full stroke or is not

developing enough force to either install a fastener or

eject off an installed fastener, it may be necessary to add

oil to the pull and return system of the tool.

1. To add fluid to the PULL or RETURN side ports, first

make sure Cutoff Valves (70) are in the fully closed

position.

2. Remove Reservoir Plugs (75) and thread two

Reservoirs (66) with O-Rings (91) in place into the

ports of the Manifold Block (68).

3. Remove the Caps (65) and Piston Assys (67) from

the Reservoirs, and add fluid to the Reservoirs.

NOTE: Do not fill past the inside shoulder of the

Reservoirs (NO higher than Vent Hole). See Step

2 of figure 6

4. Replace Piston Assemblies and Caps on

Reservoirs.

5. Open the Cutoff Valves 1/4 turn counterclockwise.

Thread Piston Assemblies down to force fluid into

the system, and until Piston Assemblies cannot be

turned further.

6. Close Cutoff Valves tightly, and check tool stroke.

Repeat Steps 3 through 5 if necessary. If stroke is

correct, install a test fastener.

7. Remove the Reservoir Assemblies and replace the

two Reservoir Plugs (75) and tighten.

CAUTION:

Oil may be present in Reservoir tubes. Remove

with care.

R

P

RETURN

PULL

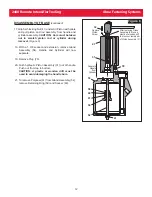

Step 1

Turn Threaded Rod of Piston Assy

counterclockwise until the Cap

unscrews out of the reservoir.

Step 2

Fill Reservoir with

hydraulic fluid to

top of piston bore

Relief

Valve (72)

Bleed Plug

Assembly (73)

Step 3

Thread Rod

down flush to

top of Cap.

Threaded

Rod

Cap (65)

Piston

Assy (67)

Reservoir

(66)

Manifold

Block (68)

Cutoff

Valves (70)

R

P

Step 4

Thread two

Reservoir Plugs

back into ports.

Vent Hole

Figure 12

WARNING: Avoid

contact with hydraulic

fluid. Hydraulic fluid

must be disposed of in

accordance with

Federal, State and

Local Regulations.

Please see MSDS for

Hydraulic fluid

shipped with tool.

!

Figure 11

F

ILL AND

B

LEED

P

ROCEDURE

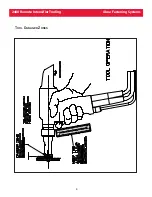

Equipment Required:

- Shop airline with 90 - 100 psi max.

- Air regulator

- Fill Bottle (94), Tube (93), and Connector (92)

(supplied with tool).

- Large flat blade screwdriver

- Nose assembly

- Fasteners (Optional)

Preparation:

1. Install air regulator in airline and set

pressure to 20-40 psi.

2. Fill bleed Bottle (94) almost full of DEXRON III

ATF or equivalent and secure Bottle cap.

(Figure 11)

3. Install Plastic Tube (93) and Connector (92) on

tip of Bottle Cap.

USE AUTOMATIC TRANSMISSION FLUID

DEXRON III, OR EQUIVALENT.

(Not to Scale)