VELTRON II

Air Monitor Corporation

116-011-98.P65 (8/30/10)

VELTRON II - IO&M Manual

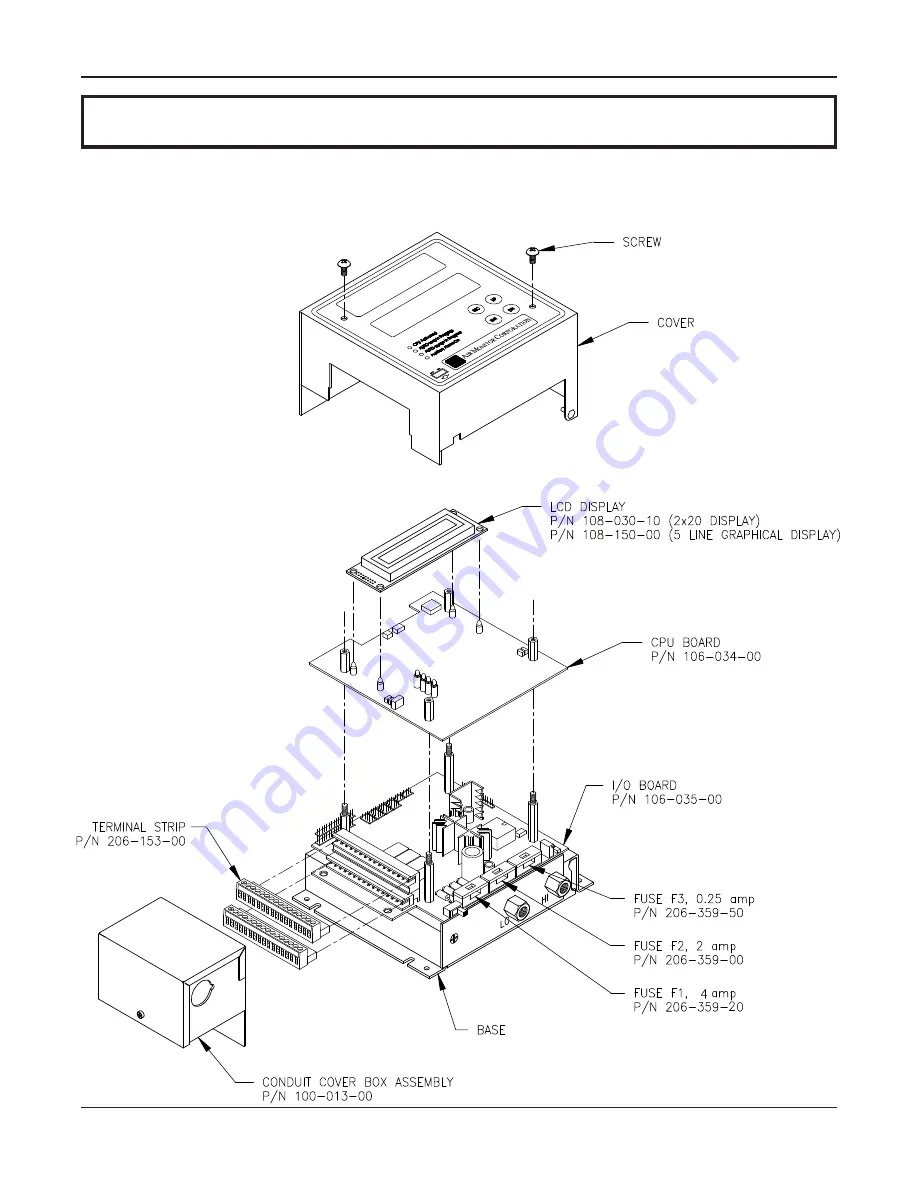

9 – PARTS LIST

The following drawing with part numbers lists components of the VELTRON II that are easily replaced by the user.

When contacting the Customer Service Department about parts, please have the applicable Factory Set-Up Information

sheet available for reference. To inquire about price and availability of a specific part number, please contact the

Customer Service Department at:

Phone: 707-544-2706

800-AIRFLOW

Fax:

707-526-2825

64

SECTION 9 – PARTS LIST

Summary of Contents for VELTRON II

Page 2: ......