13

Gen IV Controller with Smart Arm Setup Instruction Manual

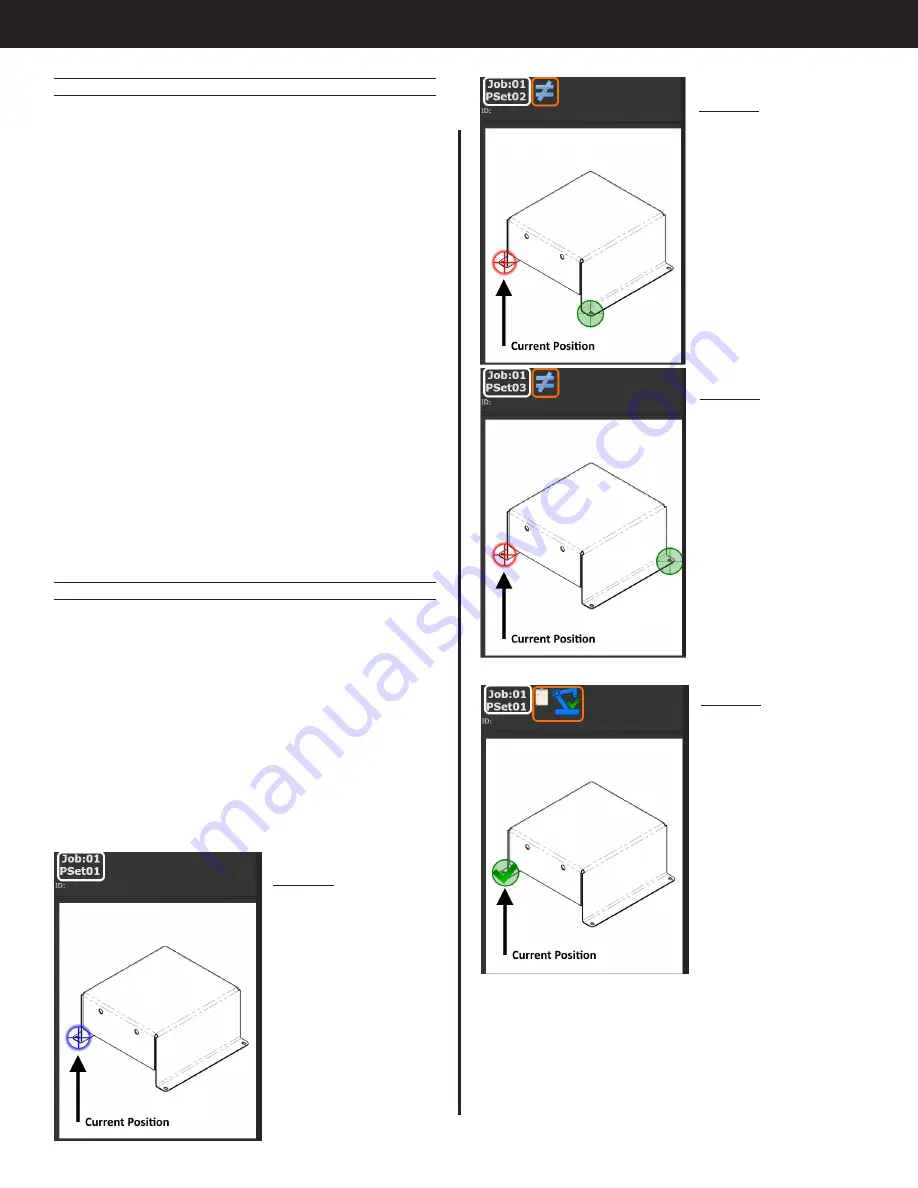

Image 5

Job Seq 2 is selected.

Arm is in position

1 (shown in red as

incorrect position) and

screen shows green

target highlighting

fastener to be

inserted. Stopped icon

appears showing that

the tool is disabled.

Image 6

Job Seq 3 is selected.

Arm is in position

1 (shown in red as

incorrect position)

and screen shows

green target

highlighting fastener

to be inserted.

Stopped icon

appears showing that

the tool is disabled.

Image 7

First fastener has been

inserted successfully.

Current position is

marked OK. Status

bar shows 'Job

Sequence Complete'

and 'Location

Complete'.

9.2.4 External Control

Line side control can be used to command which

fastener needs to be run. Select the Job that

matches the work type (initial or rework) and

select the job sequence number that is tied to the

fastener location. Configure the assignable IO for

the required interface type (CC-Link, Anybus, etc.)

to select a job number and job sequence number.

Refer to the white paper for the specific interface for

configuration details.

In this example, selecting Job 1 and Job Sequence

2 will select PSet 2 and disable the controller until the

arm is in the correct position for fastener 2.

Selecting Job 2 and Job Sequence 3 will select PSet

6 and disable the controller until the arm is in the

correct position for fastener 3.

The front panel and physical IO can be used to

select job number, sequence number, and reset

job if needed for testing. The job can be changed

by holding the toggle button and pressing an up/

down button. Job sequence can be changed by

just pressing an up or down button when jobs are

enabled.

9.2.5 Add Image for Runscreen

Add the image and three locations as shown in "9.1

9.2.5.1 Runscreen Behavior

Return to the Gen IV Runscreen and navigate to

the screen with the part image. The image will

now direct the user to fasten the bolt that is being

commanded from the ‘Select Job Sequence’ input.

The next images show what happens when the

Arm is over location 1 but the commanded Job

Sequence from IO changes from 1, 2, and then 3.

Image 4

Job Seq 1 is selected.

Arm is in correct

position.

Summary of Contents for AcraDyne

Page 15: ......