12

Gen IV Controller with Smart Arm Setup Instruction Manual

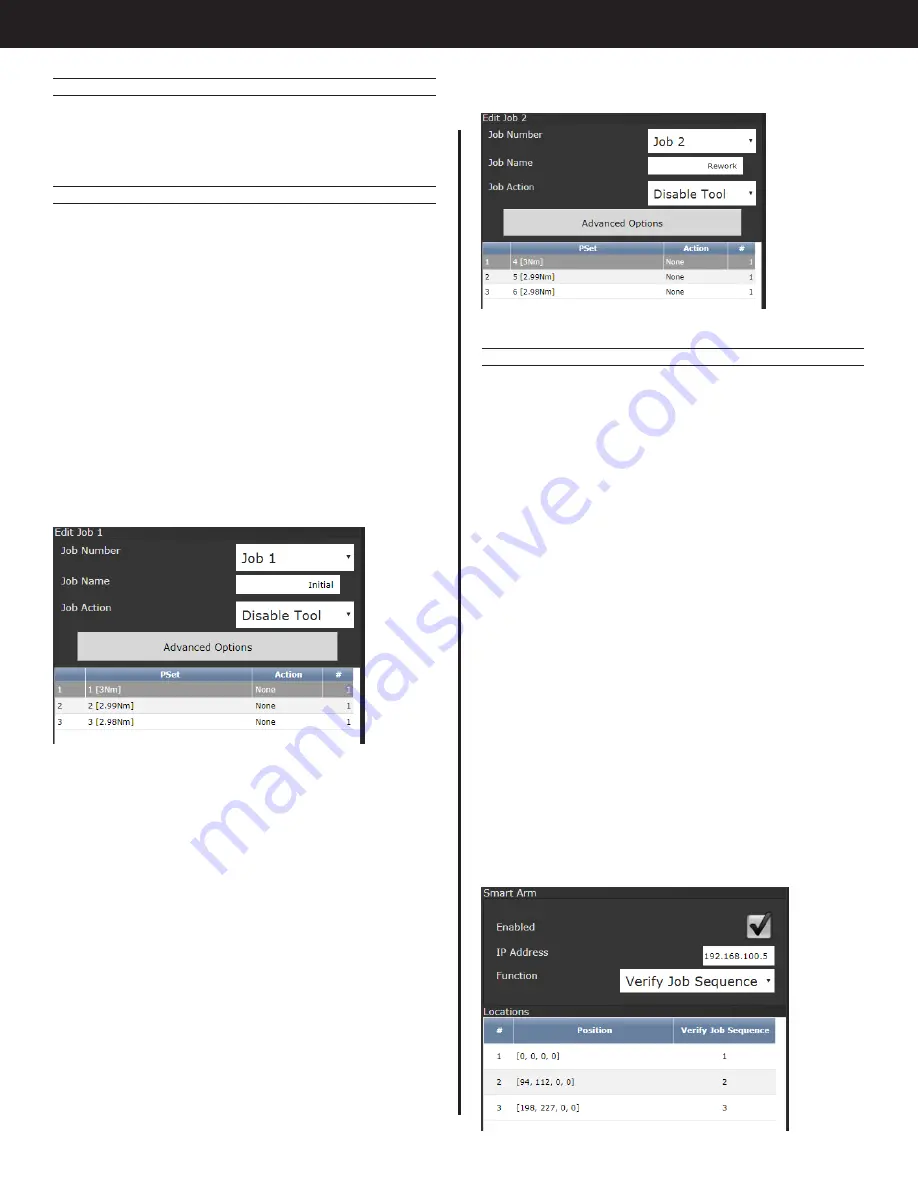

The setup should result in a job that is shown below.

9.2.3 Accessory Setup

Navigate to the Accessories screen, select the

Smart Arm accessory configured in the ‘Initial Setup’

portion and click the edit button.

Set up the accessory function as ‘Verify Job

Sequence’. This allows an external system to select

the job number and job sequence number to define

which fastener needs to be run and whether it

should be from the ‘Initial work’ job or the ‘Rework’

job.

Add three fastener locations. Click the Add(+)

button to add a new location. Set ‘Parameter’ to

1 so that job sequence 1 needs to be selected for

the tool to be enabled. Move the tool onto the

fastener for this location. Click ‘Use Current Position’

to populate the target fields with this locations

encoder values. Click OK/Check. Repeat this for

location 2 and 3. Set ‘Parameter’ to 2 for location 2

and 3 for location 3. Click OK/Check until all Smart

Arm configurations are saved.

Each location is now paired with a job sequence

number. Now configure the line side control to

select the job and job sequence paired to the

fastener and the tool will not be enabled until the

tool is located over the correct fastener.

9.2.1 PSet Setup

Set up six PSets. These can be named in the

advanced settings to make it more clear which PSet

is for which bolt.

9.2.2 Job Setup

Set up two Jobs. Name Job 1 as ‘Initial’ and Job 2 as

‘Rework’.

In job 1 set up the job sequence as the following

•

Sequence 1: PSet 1

○

Action: None

○

Count: 1

•

Sequence 2: PSet 2

○

Action: None

○

Count: 1

•

Sequence 3: PSet 3

○

Action: None

○

Count: 1

The setup should result in a job that is shown below.

In job 2, set up the job sequence as the following:

•

Sequence 1: PSet 4

○

Action: None

○

Count: 1

•

Sequence 2: PSet 5

○

Action: None

○

Count: 1

•

Sequence 3: PSet 6

○

Action: None

○

Count: 1

Summary of Contents for AcraDyne

Page 15: ......