25

21.05 - 6068956_00

NXP 0500 - 1650 2-PIPE SYSTEM / 4-PIPE SYSTEM

EN

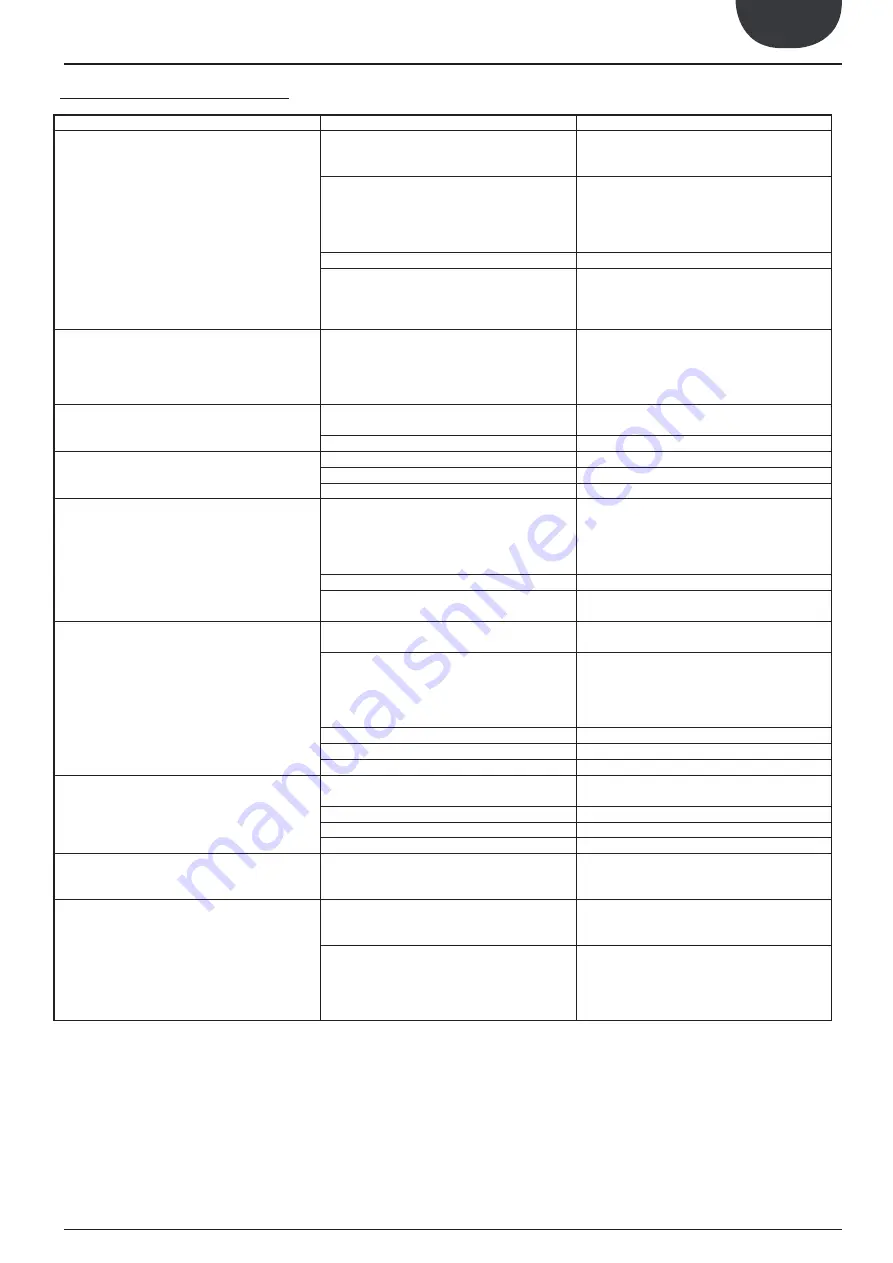

ANOMALY

CAUSE

REMEDY

The unit does not start

•

No electric voltage

• Check the presence of voltage

• Check the safety systems upstream from the appli-

ance

• Master switch at OFF

•

Remote switch at OFF (if present)

• Control panel at OFF

• Main switch at OFF

• Compressor magnet circuit breaker at OFF

•

Position at ON

•

Power supply voltage too low

• Check power supply line

• Remote control switch coil broken

• Circuit board broken

•

Peak condenser broken

• Compressor broken

• Replace the component

Insufficient yield

•

No refrigerant

• Dirty coils

• Water filter clogged

• Appliance dimensioning

• Operation outside of operational limits

• Check the load and any leaks

• Clean the coils

• Clean the filter

• Check

• Check the operational limits using the graphics

Noisy compressor

• Liquid return to the compressor

• Inadequate fixing

• Check

• Inverted phase

• Invert a phase

Noise and vibrations

• Contacts between metal bodies

• Check

• Weak support

• Restore

• Loose screws

• Tighten the screws

The compressor stops due to intervention

of the protections

• Excessive flow pressure

• Low intake pressure

• Low power supply voltage

• Electric connections fastened badly

• Operation outside of operational limits

• Check the operational limits using the graphics

•

Pressure switch malfunctioning

• Replace the component

• Circuit breaker protection intervention

• Check power supply voltage

• Check electric isolation of the windings

Compressor high discharge pressure

• High external water temperature

• High utility water inlet temperature

• Check the operational limits using the graphics

• Insufficient air flow

• Insufficient water flow

• Check:

1. Fan operation

2. Cleanliness of the coils

3.

Pump operation (speed)

4. Filter cleanliness

• Fan regulation anomalous operation

• Check or replace if broken

• Air in the hydraulic system

• Bleed the circuit

• Excessive refrigerant gas load

• Restore the correct load

Low discharge pressure

• Low external air temperature

• Low inlet water temperature

• Check the operational limits using the graphics, as

above

• Humidity in the cooling circuit

• Empty and restore the gas load

• Air in the hydraulic system

• Bleed the circuit

• Insufficient gas load

• Restore the correct load

High intake pressure

• High external air temperature

• High utility inlet water temperature

• Thermostatic expansion valve too open or damaged

• Check the operational limits using the graphics

• Adjust or replace if damaged

Low intake pressure

• Low utility water inlet temperature

• Low external water inlet temperature

• Thermostatic expansion valve damaged or blocked

• Check the operational limits using the graphics

• Adjust or replace if damaged

• Insufficient water flow

• Insufficient air flow

• Check:

1. Fan operation

2. Cleanliness of the coils

3.

Pump operation (speed)

4. Filter cleanliness

TROUBLE SHOOTING

19. TROUBLE SHOOTING