23

21.05 - 6068956_00

NXP 0500 - 1650 2-PIPE SYSTEM / 4-PIPE SYSTEM

EN

CONTROL AND COMMISSIONING

PREPARATION FOR COMMISSIONING

Please note that, on request by the Aermec customer or

the legiti mate owner of the machine, the units in this se-

ries can be started up by the AERMEC A� er-Sales Service

in your area (valid only on Italian territory).

The start of operati on must be scheduled in advance

based on the frame regarding the realisati on of the sys-

tem. Prior to the interventi on, all other works (electrical

and hydraulic connecti ons, priming and bleeding of air

from the system) must have been completed.

START - UP

PRELIMINARY OPERATIONS TO BE PERFOR-

MED WITH NO VOLTAGE PRESENT

Control:

1.

All safety conditi ons have been respected.

2.

The unit is correctly fi xed to the support

surface.

3.

The minimum technical spaces have been

respected.

4.

That the main power supply cables have

appropriate cross-secti on, which can support

the total absorpti on of the unit

(see electric

data secti ons)

and that the unit has been duly

connected to earth.

5.

That all the electrical connecti ons have been

made correctly and all the clamps adequately

ti ghtened.

THE FOLLOWING OPERATIONS ARE TO BE CAR-

RIED OUT WHEN THE UNIT IS LIVE.

1.

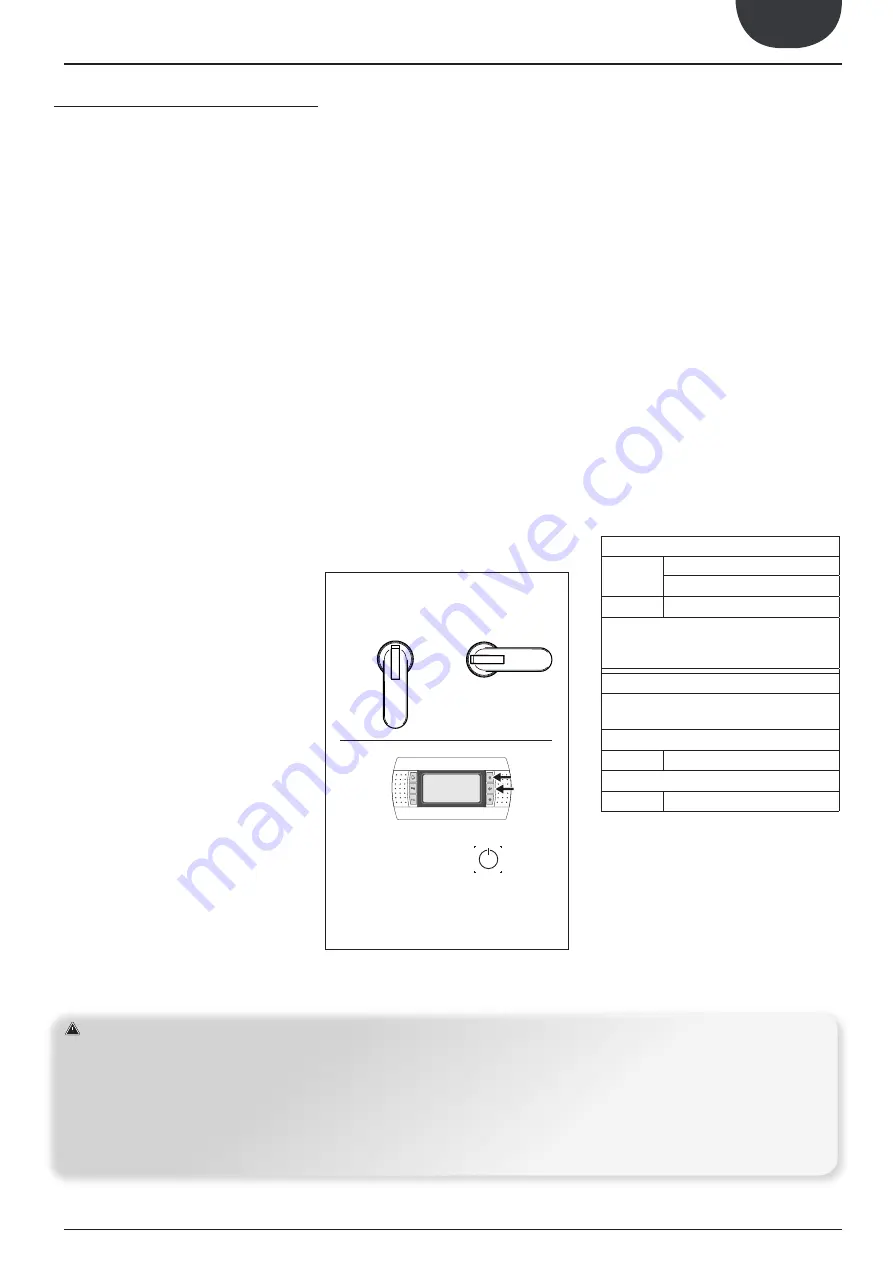

Supply power to the unit by turning the master

switch to the ON position; see (fig1.) The display

will switch on a few seconds after voltage has

been supplied; check that the operating status

is on OFF (OFF BY KEY B on lower side of the

display).

2.

Check with a tester that the value of the supply

voltage to the phases: single-phase – three-phase

is within the present limits: ±10% (230V ±10% -

400V ±10%), and that the unbalance between the

phases is not more than 3% (only for three-phase

models)

3.

Check that the connections made by the installer

are in compliance with the documentation.

4.

Verify that the compressor sump resistance/s

is/are operating by measuring the increase in

temperature of the oil pan. The resistance/s must

function for at least 12 hours before start-up of

the compressor and in any event, the tempera-

ture of the oil pan must be 10-15°C higher than

room temperature.

HYDRAULIC CIRCUIT

1.

Check that all hydraulic connections are made

correctly, that the plate indications are complied

with and that a mechanical filter has been

installed at the evaporator inlet

(mandatory

component for warranty to be valid).

2.

Make sure that the circulation pump/s is/are

operating and that the water flow rate is

sufficient to close the flow switch contact.

3.

Check the water flow rate, measuring the

pressure difference between evaporator inlet

and outlet and calculate the flow rate using the

evaporator pressure drop diagram present in

the technical manual

(available on the software

selection and on the website www.aermec.com

4.

Check correct operation of the flow meters, if

installed (or supplied with the unit or by the

installer – see the chapter of hydraulic circuit to

know the components supplied with the unit):

•

Flow switch/Pressure switch:

on closing the

cut-off valve at the heat exchanger outlet, the unit

must display the block. Finally, open the valve and

rearm the block.

MACHINE COMMISSIONING

The unit can be used a� er all of the above-menti oned

controls have been performed.

- Close the electric control board hatch.

- Positi on the appliance master switch at ON

- Starting the unit

WITH THE MACHINE ON, CHECK

COOLING CIRCUIT

CHECK:

- That the compressor input current is lower than the

maximum indicated in the technical data table.

- That in models with three-phase power supply, the

compressor noise level is not abnormal. If this is the

case, invert a phase.

- That the voltage value lies within the pre-fixed limits

and that unbalance between the three phases (three-

phase power supply) is not above 3%.

- The presence of any refrigerant GAS leaks, parti cu-

larly in correspondence with the manometers pres-

sure transducers and pressure switches pressure

points (vibrati ons during transportati on may have

loosened the fi � ngs).

- Overheating

Comparing the temperature read using a contact

thermostat positioned on the compressor intake with

the temperature shown on the low pressure manom-

eter (saturation temperature

corresponding to

the evaporation pressure). The difference between

these two temperatures gives the

over-

heating value. Optimal values are between 4 and 8°C.

- Pressing line temperature. If the subcooling and

overheating values are regular, the temperature

measured in the pressing line pipe at the outlet of

the compressor must be 30/40°C above the conden-

sation temperature.

Operati ng features (Factory set)

7°C / ∆t=5°C

Cooling Only

Heat Pump in Cooling Mode

45°C / ∆t=5°C Heat Pump in Heati ng Mode

If the unit power supply is restored a� er a tempo-

rary interrupti on, the mode set will be kept in the

memory.

Compressor Start-Up Delay

Two functi ons have been set-up to prevent com-

pressor start-ups that are too close.

Minimum time from last switch-off

60 seconds

in Cooling Mode

Minimum time from last switch-on

300 seconds

in Heati ng mode

ATTENTION

1)

Commissioning must be performed with standard settings.

Only when the inspection has been completed can the functio-

ning Set Point values by changed.

Before start-up, power the unit for at least 12-24 hours, posi-

tioning the protection magnet circuit breaker switch and the

door lock isolating switch at ON.

Make sure that the control panel is off in order to allow the

compressor oil sump to heat.

2)

We recommend to envision a machine book (not

supplied, but the user’s responsibility), which allows to keep

track of the interventions performed on the unit.

In this way it will be easy to suitably organise the interventions

making research and the prevention of any

machine breakdowns easier. Use the date to record date, type

of intervention made (routine maintenance, inspection or re-

pairs), description of the intervention,

measures actuated.

3)

It is forbidden to LOAD the cooling circuit with a refrigerant

different to that indicated. Using a different refrigerant gas can

cause serious damage to the unit.

ON

ON

OFF

OFF

SELECT MENÙ

ON/OFF

16. CONTROL AND COMMISSIONING