16

21.05 - 6068956_00

NXP 0500 - 1650 2-PIPE SYSTEM / 4-PIPE SYSTEM

EN

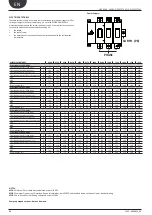

The units are completely wired at the factory and only

require connecti on to the electrical mains, downstream

from a unit switch, according to that envisioned by

the Standards in force on this subject in the country of

installation.

It Is also advised to check that:

1.

The electrical mains features are suitable for the

input values indicated in the electrical data table,

also taking any other machines operating at the

same time into consideration.

2.

The unit must only be powered when installation

has been completed (hydraulic and electric).

3.

Respect the connection indications of the phase

and earth wires.

4.

The power supply line must have a relevant protec-

tion against short circuits mounted upstream and

dispersions to earth, which isolate the system with

respect to other utilities.

5.

The voltage must be within a tolerance of ±10% of

the nominal power supply voltage of the machine

(for unbalanced three-phase unit max 3% between

the phases). Whenever these parameters are

not respected, contact the electric energy public

body.

6.

For electric connections, use the cables with dou-

ble isolation according to the Standards in force on

this subject in the different countries.

THE FOLLOWING ARE MANDATORY

1.

The use of an omnipolar magnet circuit breaker

switch is mandatory, in compliance with the IEC-EN

Standards (contact opening at least 3 mm), with

suitable cut-off power and differential protection

on the basis of the electric data table shown below,

installed as near as possible to the appliance.

2.

It is mandatory to make an effective earth connec-

tion. The manufacturer is not liable for any damage

caused by the lack of or ineffective appliance earth

connection.

3.

For units with three-phase power supply, check the

correct connection of the phases.

4.

It is mandatory to verify that the machine is water-

ti ght before making the electrical connecti ons and

it must only be powered a� er the hydraulic and

electrical works have been completed.

All the electrical operati ons must be carried out by

STAFF

IN POSSESSION OF THE NECESSARY QUALIFICATIONS

BY LAW,

suitably trained and informed on the risks related

to these operati ons.

The features of the electrical lines and of the related

components must be determined by

STAFF QUALIFIED

TO DESIGN ELECTRICAL SYSTEMS,

in compliance with

the internati onal and nati onal regulati ons of the place of

installati on of the unit and in compliance with the regula-

ti ons in force at the ti me of installati on.

For the installati on requirements refer only to the wiring

diagram supplied with the appliance.

THE WIRING DIAGRAM ALONG WITH THE MANUALS

MUST BE KEPT IN GOOD CONDITION AND ALWAYS

BE AVAILABLE FOR ANY FUTURE INTERVENTIONS ON

THE UNIT.

ATTENTION

1. It is prohibited to use the water pipes to earth the

appliance.

2.

Check the tightening of all power wire clamps on

commissioning and after 30 days from start-up.

Successively check them every six months.

Loose terminals can cause overheating of the

cables and components.

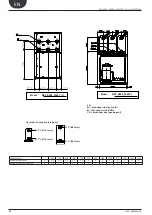

ELECTRIC CONNECTIONS

1.

Before connecti ng the unit to the power supply mains,

make sure that the isolati ng switch is open.

2.

Open the front panel.

3.

Use the plates to pass the main electric power supply

cable and the cables of the other

external connecti ons under the responsibility of

the installer.

4.

It is prohibited to access positi ons not specifi cally envi-

sioned in this manual with electric cables.

5.

Avoid direct contact with non-insulated copper

piping and with the compressor.

6.

Identi fy the clamps for the electric connecti on

and always refer exclusively to the wiring dia-

gram supplied with the unit.

7.

For the functi onal connecti on of the unit, take

the power supply cable to the electric control

board inside the unit and connect it to clamps.

L1-L2-L3 and PE respecti ng the polariti es.

L1-L2-L3 as phases, and PE as earth;

8.

Re-positi on the inspecti on panels.

9.

Ensure that all protecti ons removed for the

electric connecti on have been restored before

powering the unit electrically.

10.

Positi on the system master switch (outside the

appliance) at “ON”.

1. ELECTRIC POWER CONNECTION TO THE ELECTRICAL MAINS

ON

OFF

Holes for passage of electric cables

Master Switch ON/OFF

Restoring the

protection degree of

the electrical box by

the installer

9. ELECTRIC CONNECTIONS