11

21.05 - 6068956_00

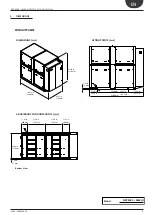

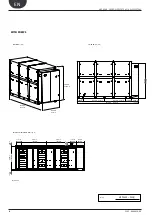

NXP 0500 - 1650 2-PIPE SYSTEM / 4-PIPE SYSTEM

EN

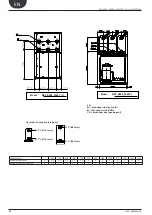

MAIN HYDRAUL IC CIRCUITS

INTERNAL HYDRAULIC CIRCUIT

Model:

HYDRAULIC COMPONENTS

RECOMMENDED OUTSIDE THE UNIT

ATTENTION

..........................................................

1.

The choice and installation of compo-

nents outside the units is the installer's

responsibility, who must operate ac-

cording to the code of practice and in

compliance with the Standard in force

in the country of destination.

2.

The hydraulic connection pipes to the

machine must be suitably

dimen-

sioned for the effective water flow rate

requested by the system when run-

ning. The water flow rate to the heat

exchanger must always be constant.

3.

Wash the system thoroughly before

connecting the unit. This cleaning

operation will eliminate any residues

such as welding drips, scale, rust, or

other impurities from the piping. These

substances can also deposit inside and

cause machine malfunctioning. The

connection piping must be adequate-

ly supported so that its weight is not

borne by the appliance.

4. An appropriate load/reintegration

system must be prepared

(if not in-

stalled),

which is engaged on the re-

turn line, along with a drain cock in

the lowest part of the system. Water

disconnectors must be used in systems

loaded with anti-freeze or where par-

ticular legal provisions apply. Particular

supply/reintegration waters must be

conditioned with appropriate treat-

ment systems. The

"water features"

provided in the table can be used as a

reference.

5.

It is prohibited to release water-glycol

mixtures into the environment.

6.

It is recommended to design systems

with high water content (minimum

recommended values shown in table),

in order to limit:

•

The hourly number of inversions be-

tween operating modes.

•

Drop in water temperature during win-

ter defrost cycles.

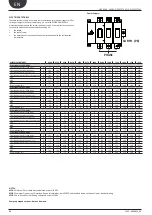

WATER FEATURES

PH

6-8

Electric conductivity

Less than 200 mV/cm (25°C)

Chloride ions

Less than 50 ppm

Sulphuric acid ions

Less than 50 ppm

Total iron

Less than 0.3 ppm

Alkalinity M

Less than 50 ppm

Total hardness

Less than 50 ppm

Sulphur ions

none

Ammonia ions

None

Silicone ions

Less than 30 ppm

RECOMMENDED MINIMUM WATER CONTENT

NXP WITHOUT PUMPS

4. MAIN HYDRAULIC CIRCUIT

5

1

3

6

6

13

13

13

4

4

4

9

2

12

EV

7

7

7

10

11

8

4

9

15

14

6

6

5

5

5

5

5

1

3

13

2

13

4

9

12

REC

7

7

13

10

11

8

4

9

15

4

7

6

6

5

1

3

13

4

13

4

9

12

CN

13

7

7

7

14

15

8

COMPONENTS SUPPLIED AS PER STANDARD

1

- Plate exchanger

5 - Water temperature probes (IN/OUT)

RECOMMENDED COMPONENTS NOT

SUPPLIED FOR WHICH INSTALLER IS RESPONSIBLE

2 - Water filter

3 - Fow switch

4 - Air vent valve

6 - Anti-vibration joints

7 - Cut-off valve

8 - Safety valve

9 - Expansion Tank

Exchanger side (hot/cold)

Exchanger side (DHW)

Exchanger side (geothermal)

10 -

System buffer tank (installation recommended

whenever the system water content is less than

that indicated in tab.)

11 - Antifreeze electric heater

12 - Pump

13 - Drain valve

14 - Gauge

15 - Automatic fill point

NXP

0500

NXP

0550

NXP

0600

NXP

0650

NXP

0700

NXP

0750

NXP

0800

NXP

0900

NXP

1000

NXP

1250

NXP

1400

NXP

1500

NXP

1650

n°/n°

3/2

3/2

4/2

4/2

4/2

4/2

4/2

4/2

4/2

4/2

4/2

4/2

4/2

l/kW

7

7

7

7

7

7

7

7

7

7

7

7

7

l/kW

14

14

14

14

14

14

14

14

14

14

14

14

14

MINIMUM WATER CONTENT

Compressors / Circuits

System side | Recovery side

RECOMENDED WATER CONTENT

System side | Recovery side

(*)Minimum water content for process applications or operating at low external temperatures and low load.

Control on leaving water temperature.

Design Δt less than 5°C.