C N C 4 2 2 0 M a c hi ne Too l Op e ra t ion an d Te st

43

electric impact to the equipment;

Note 3: After relieving the alarm, please re-execute the mechanical reset operation to ensure

the accuracy of the coordinates (if the machine tool doesn’t have mechanical origin, do

not perform this operation);

Note 4: The function is valid only when the value is set to 1.

8.1.3

AUTOMATIC RUNNING IN ANY SECTION

Under certain conditions, it is necessary to start running from a line in the processing program.

This system allows starting running from any section of current program. The specific operation

follows:

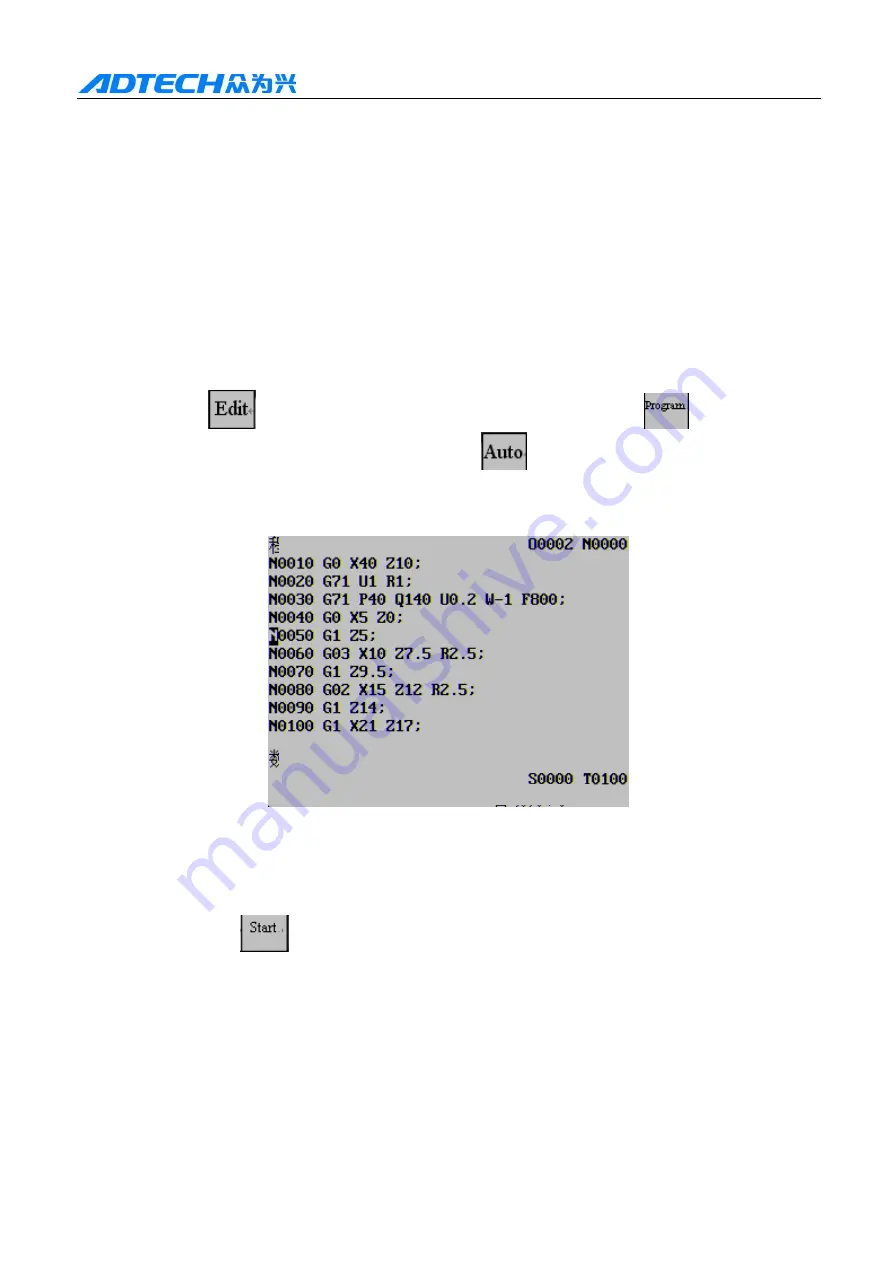

A. Press the Edit

key to enter the editing mode, press the Program key

to enter the

program display page, and then press the Auto key

to enter the auto mode;

B. Move the cursor to the program section to start running (for example, to start running from N0050,

move the cursor to instruction word N0050);

C. Move the knife to the end position after the previous program section of the current program

section has run.

D. If the current mode state isn’t consistent to the mode state before running this program section,

please perform the corresponding mode function and state;

E. Press the Start key

to start the program.

8.1.4

FEEDING MAGNIFICATION REGULATION

During automatic running, you can change the running speed by regulating the feeding

magnification in this system, and don’t need to change the speed set in the program and

parameters.

Program

Data=

Manual mode