BusWorks

Model 903MB/902MB/901MB Network I/O Module User’s Manual Digital I/O

___________________________________________________________________________________________

- 4 -

RS-232 to RS-485 Serial Adapter (Model 5034-214)

This device is a non-isolated, port-powered, signal converter

for communication between the RS-232 serial port of a personal

computer and the RS-485 network interface of Series 900MB I/O

Modules. It is used in conjunction with the Acromag

Configuration Software for simple reconfiguration, testing, and

troubleshooting of Series 900MB I/O modules. As a port-

powered device, it is not intended for driving fully loaded RS-485

networks over long distances, and does not have sufficient power

to drive terminated networks. The adapter has DB-9F connectors

at both ends and plugs directly into the common DB-9M serial

port connector of most personal computers. The module is

connected to the RS-485 side of this adapter via a separate

interconnecting cable (see Cable 5034-202 described below).

Interface Cable (Model 5034-202)

This 3-wire cable is used to connect the RS-485 side of

Signal Converter 5034-214 to the RS-485 network terminals of

Series 900MB modules. This cable is 8 feet long and has a

DE-9M connector on one end, and three stripped and tinned

wires on the other end. The wires are labeled A, B, and C for

connection to the module D, Dbar, and COM terminals,

respectively.

Series 900MB Software Interface Package (Model 900C-SIP)

The 900C-SIP Software Interface Package combines the

900MB Configuration Software (5034-186), RS-232 to RS-485

Serial Converter (5034-214), Interface Cable (5034-202), and

Instructions (8500-649), into a complete kit for interfacing with

Series 900MB I/O Modules.

2.0 PREPARATION FOR USE

UNPACKING AND INSPECTION

Upon receipt of this product, inspect the shipping carton for

evidence of mishandling during transit. If the shipping carton is

badly damaged or water stained, request that the carrier's agent

be present when the carton is opened. If the carrier's agent is

absent when the carton is opened and the contents of the carton

are damaged, keep the carton and packing material for the

agent's inspection. For repairs to a product damaged in

shipment, refer to the Acromag Service Policy to obtain return

instructions. It is suggested that salvageable shipping cartons

and packing material be saved for future use in the event the

product must be shipped.

This module is physically protected

with packing material and electrically

protected with an anti-static bag during

shipment. However, it is

recommended that the module be

visually inspected for evidence of

mishandling prior to applying power.

This circuit utilizes static sensitive

components and should only be

handled at a static-safe workstation.

MODULE INSTALLATION

This transmitter module is packaged in a general purpose

plastic enclosure. Use an auxiliary enclosure to protect the unit in

unfavorable environments or vulnerable locations, or to maintain

conformance to applicable safety standards. Stay within the

specified operating temperature range. As shipped from the

factory, the unit is calibrated for all valid input ranges and has the

default configuration shown in Table 2 below:

WARNING:

Applicable IEC Safety Standards may require that

this device be mounted within an approved metal enclosure or

sub-system, particularly for applications with exposure to voltages

greater than or equal to 75VDC or 50VAC.

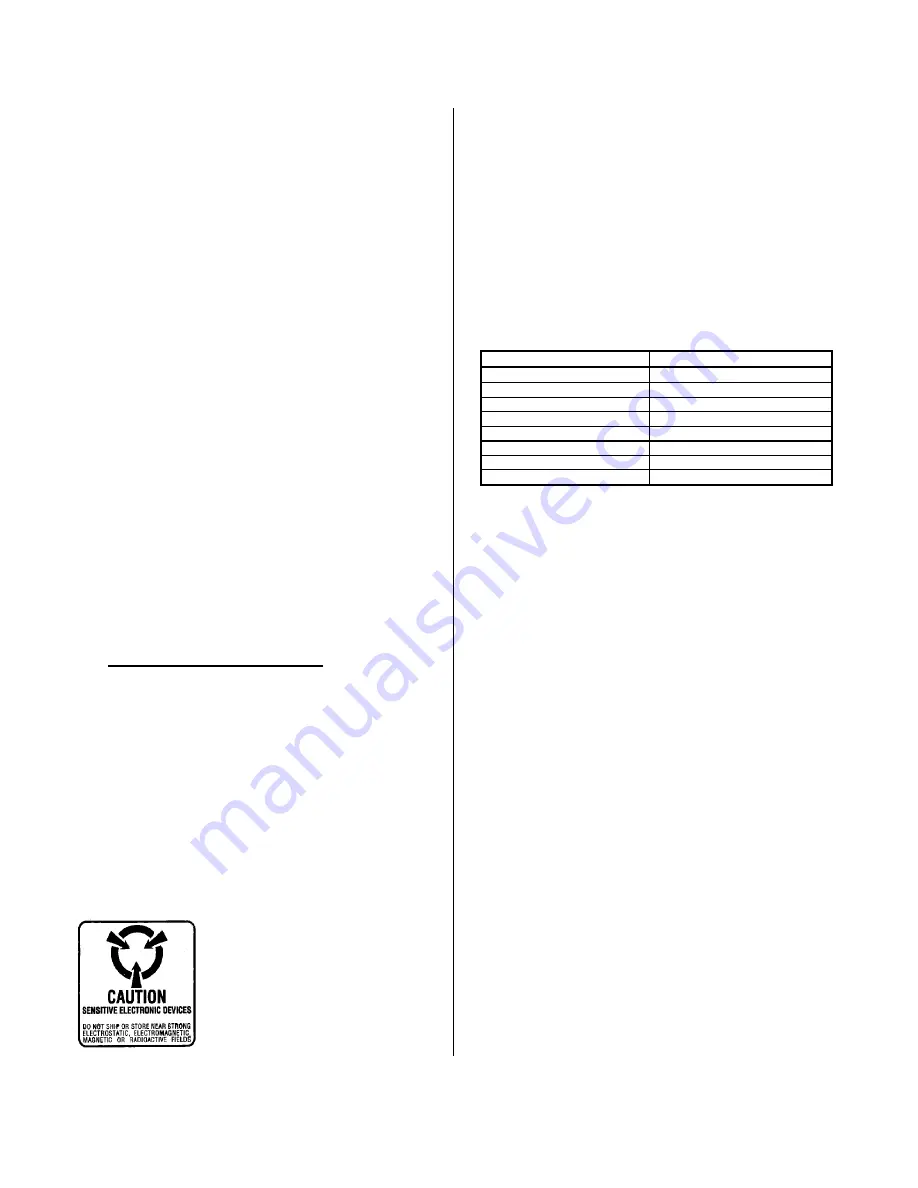

Table 2: 903MB Default Factory Configuration

PARAMETER

CONFIGURATION

Module Address

247

Baud Rate

9600bps

Parity

None

Stop Bits

1 or 2 (When Parity = None)

Response Delay

0 (No Additional Delay)

Watchdog Time (Each Port)

0 (Disabled)

Timeout State (Each Port)

65535 (FFFFH) = No Change

Pullup Resistor To EXC+

5.6K Installed (In Sockets)

Note:

Do not confuse the Default Factory Configuration noted

above with the Default Communication Mode, which refers to the

fixed baud rate, module address, parity, and stop bit settings

achieved by pushing the Default Mode button until the status LED

flashes ON/OFF. The Default Communication Mode will

temporarily over-ride any factory configuration of baud rate,

module address, parity, and stop bits with settings of 9600bps,

247, None, and 1 or 2, respectively. It is provided as a

convenient means of achieving communication with a module

when these parameters are unknown.

Your application will typically differ from the default factory

configuration and will require that the transmitter be reconfigured

to suit your needs. This can be easily accomplished with

Acromag’s user-friendly Windows 95/98

or NT

900MB

Configuration Program. Configuration is normally done prior to

field installation. Refer to MODULE SOFTWARE

CONFIGURATION of Section 3.0 for detailed instructions.

Default Mode Switch

A push-button default mode switch (DFT) and status LED are

provided at the front of the module as a convenient way of

communicating with the module when its baud rate and address

settings are unknown. Push & hold this button until the Status

LED flashes ON/OFF to indicate the module is in the Default

Communication Mode with a fixed module address of 247, baud

rate of 9600bps, no parity, and 1 or 2 stop bits. It is most

convenient to configure a module in this mode, then leave the

default mode by pressing this button again until the Status LED

stops flashing (constant ON or OFF), or by resetting the module.

Note that a rapidly flashing Status LED indicates a watchdog

timer timeout has occurred and this may temporarily mask default

mode indication. The Default Mode is disabled following a

software or power-on reset. New communication parameters (for

baud rate, address, and parity) will take effect following a reset of

the module and the module will leave the Default Mode.