66

(

r

o

r

r

E

e

r

u

t

a

r

e

p

m

e

T

)

C

)

o

F

(

r

o

r

r

E

e

u

l

a

v

F

1

.

0

%

3

.

2

1

.

0

–

%

3

.

2

–

5

.

0

%

0

.

2

1

5

.

0

–

%

0

.

1

1

–

0

.

1

%

0

.

6

2

…6

CONFIGURATION – ADVANCED LEVEL

…6.2.5

Fvalue

It is important to note the large change in equivalent sterilizing

time which results from a small increase in the sterilizing

temperature. Going from 121

C to 122

C, an increase of only

1

C, reduces the time needed to kill an equal number of

organisms by a factor of 26%. Likewise, a measurement error

which results in the set point being 1

C too low could result in a

product not being sterilized properly.

Using the advanced process recorder with its highly accurate

temperature measurement and exceptional reliability can pay

large dividends in increased productivity. Normally the sterilizing

time must be increased to compensate for the uncertainty of the

temperature measurements. The instrument reduces this

uncertainty and allows the process engineer to reduce

sterilization cycle times.

Accuracy

As the Fvalue calculation is essentially a logarithmic function

,

the

effect of measurement errors is significant on the resultant

Fvalue.

The table below shows the resultant error in the Fvalue resulting

from various measurement errors

with a Z value of 10

C:

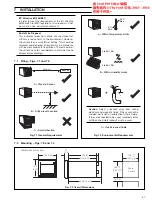

The instrument can measure TC and RTD inputs with an

accuracy of better than 0.1%. This results in superior Fvalue

calculation accuracy.

To improve the accuracy even further the Scale Adjust facility

can be used to adjust the individual channel readings to be

correct at the sterilizing temperature.

As Fvalue calculation is an integrating function, the sample rate

has a direct effect on the accuracy when the temperature is

changing. With a steady state signal the sample rate does not

affect accuracy.