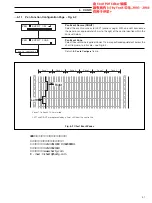

65

Time (minutes)

C

A

B C

E F

140

120

100

80

60

40

20

D

6

CONFIGURATION – ADVANCED LEVEL…

6.2.5

Fvalue

Application

The application of Fvalue measurement enables sterilizing

cycles to be shortened, relative to the traditional time versus

temperature cycles commonly adopted.

This in turn leads to greater throughput, reduced energy

consumption and minimization of product degradation due to

over exposure to high temperatures.

The most widely used method of sterilization is to heat the

product after it has been sealed into its final container, using

saturated steam maintained at a high temperature in a

pressurized autoclave oven. Steam is used because of superior

heat transfer characteristics, compared to dry air.

Heat’s ability to kill micro-organisms varies with the type of

organism and increases exponentially with increasing

temperature. By definition the steam sterilization (Fo) has a

target sterilization of 121.1

C and dry heat sterilization (Fh) a

target sterilization temperature of 170

C.

Example

– an increase of 10

C from 121.1 to 131.1

C in the

steam sterilizing temperature of the

Bacillus Stearo-thermphilus

organism increases the death rate by a factor of ten.

The change in sterilization temperature which causes a factor-

of-10 change in the death rate is unique to each organism and

is called the Z value.

Although 121.1

C is universally accepted as a reference for

steam sterilization processes, the actual sterilizing temperature

varies, depending on the products involved and on each

sterilization process.

Calculation – Fig. 6.3

The advanced process recorder’s

advanced Fvalue

implementation takes the Fvalue into account and allows the

process engineer to compute both steam (Fo) and dry heat (Fh)

results, with user defined target sterilization temperatures and Z

values.

The function implemented within the instrument can be used to

calculate any Fvalue with the general formula:

Fvalue(t) = Fvalue(t – 1) +

60

sample rate

(

)

(T

o

– T

t

)

Z

(

10

)

Where:

Fvalue(t)

– current Fvalue sum

Fvalue(t – 1)

– Fvalue sum at last sample

T

o

– measured temperature

T

t

– target sterilizing temperature

Z

– temperature interval representing a

factor of 10 reduction in killing efficiency

(Z factor)

Sample Rate

– 0.48 seconds

The Fvalue sum (in minutes) gives an equivalent time at the

target sterilization temperature taking into account the time

taken to approach and the time exceeding the target sterilization

temperature.

Example

– A typical steam sterilizing cycle – see Fig. 6.3.

The period AB is the chamber evacuation part of the cycle, when

the chamber is alternatively evacuated and purged with steam

to remove air. The ramp up to final sterilizing temperature starts

at B. The thermal conductivity of the load determines the time

taken to achieve point D, but is typically 30% of the total cycle

time. It is in the area, C D, and E F, that Fvalues make their

contribution to shortening sterilization time, by accumulating

credit for the time spent approaching and receding from the

sterilizing temperature.

Fig. 6.3 Typical Steam Sterilization Cycle