A070837 V3 EN

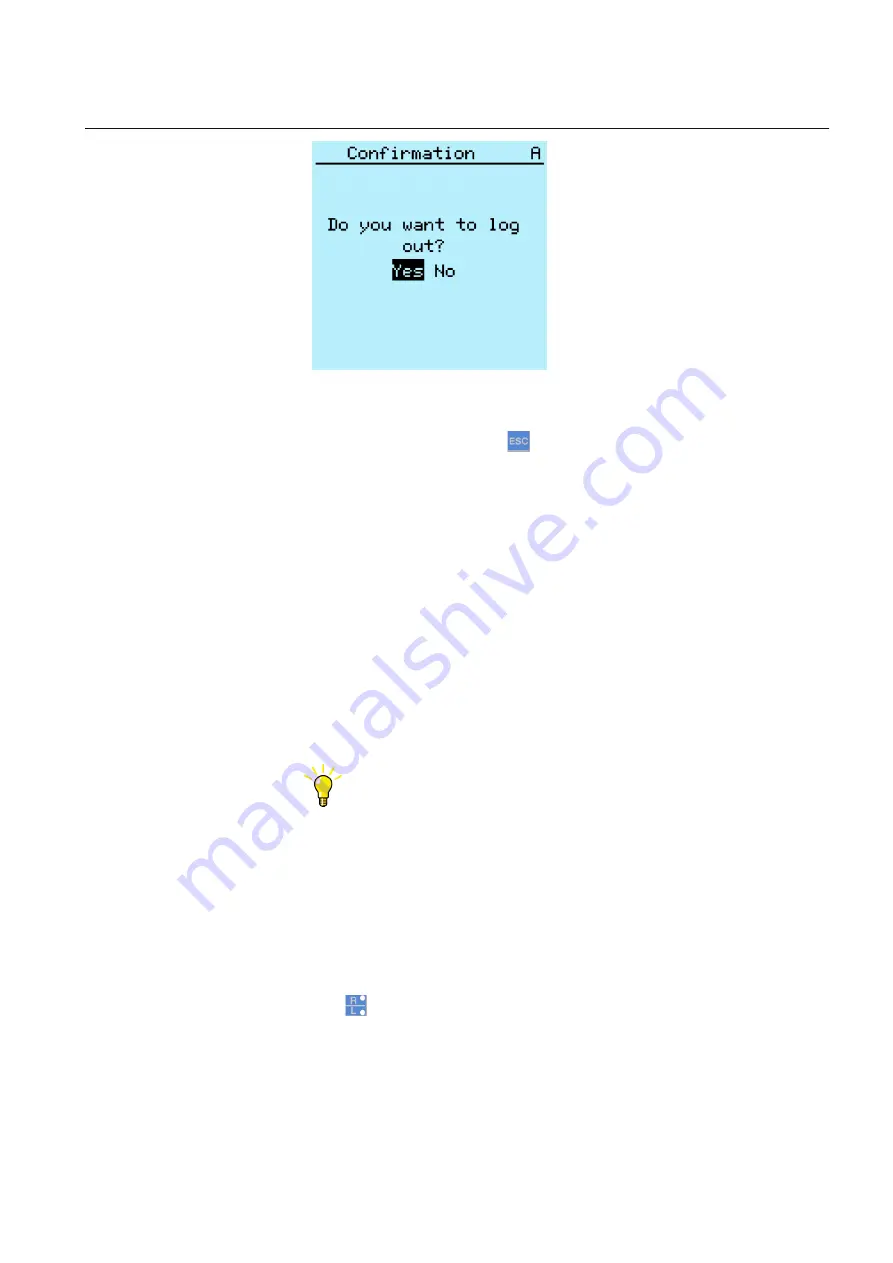

Figure 11:

Logging out

•

To cancel logout, press

.

4.1.3

Turning the display backlight on

The display backlight is normally off. It turns on during the display test at power up.

•

To turn on the backlight manually, press any LHMI push button.

The backlight turns on and the panel is ready for further operations.

If the panel has not been used for a predefined timeout period, the backlight is

switched off. The user is logged out from the current user level 30 seconds after the

display backlight has turned off.

The display returns to the default view and all unconfirmed operations such as

parameter editing and breaker selection are cancelled.

Change the backlight timeout period in

Main menu/Configuration/

HMI/Backlight timeout

.

4.1.4

Selecting local or remote use

The control position of the IED can be changed with the R/L button. In local

position primary equipment, such as circuit breakers or disconnectors, can be

controlled via the LHMI. In remote position, control operations are possible only

from a higher level, that is from a control center.

•

Press

for two seconds.

•

When the L LED is lit, local control is enabled and remote control disabled.

•

When the R LED is lit, remote control is enabled and local control disabled.

•

When neither of the LEDs is lit, both control positions are disabled.

1MRS756708 C

Section 4

Using the HMI

615 series

33

Operation Manual